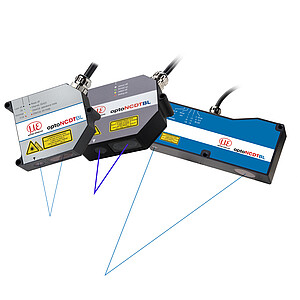

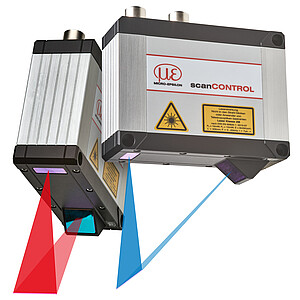

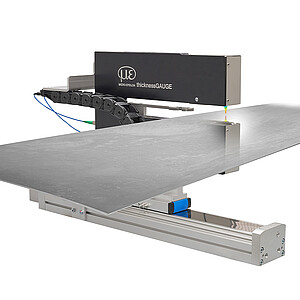

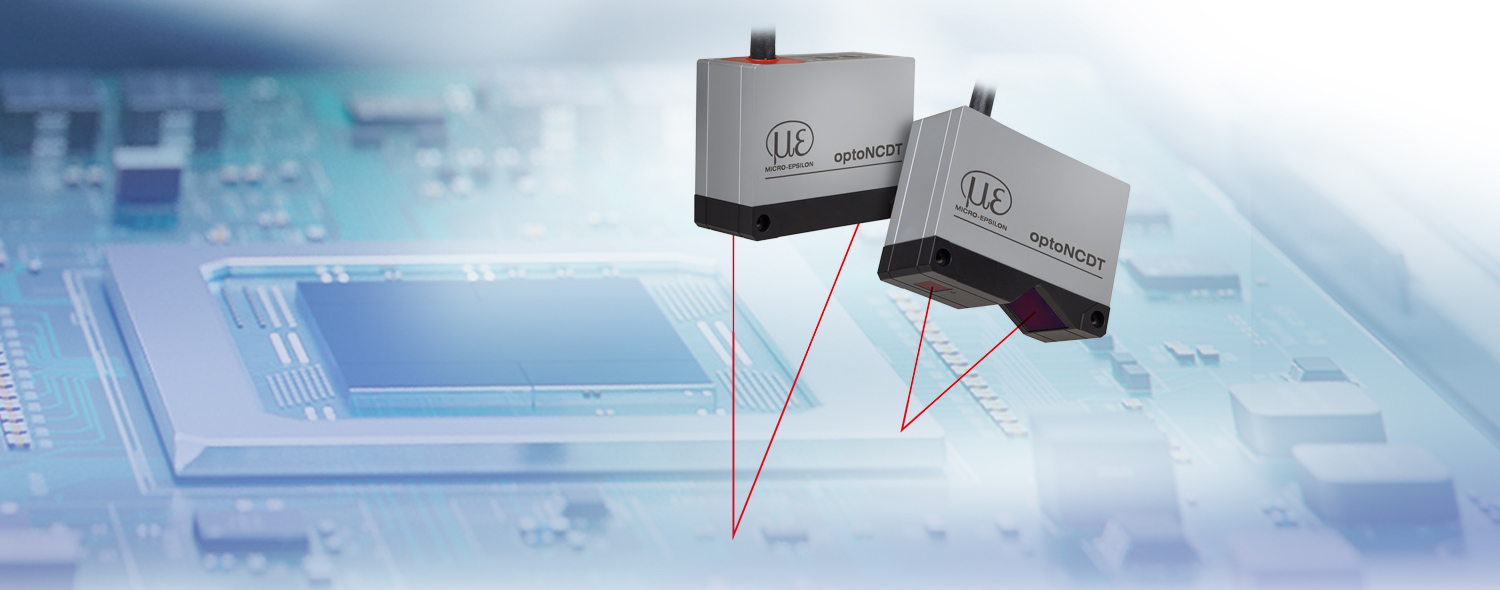

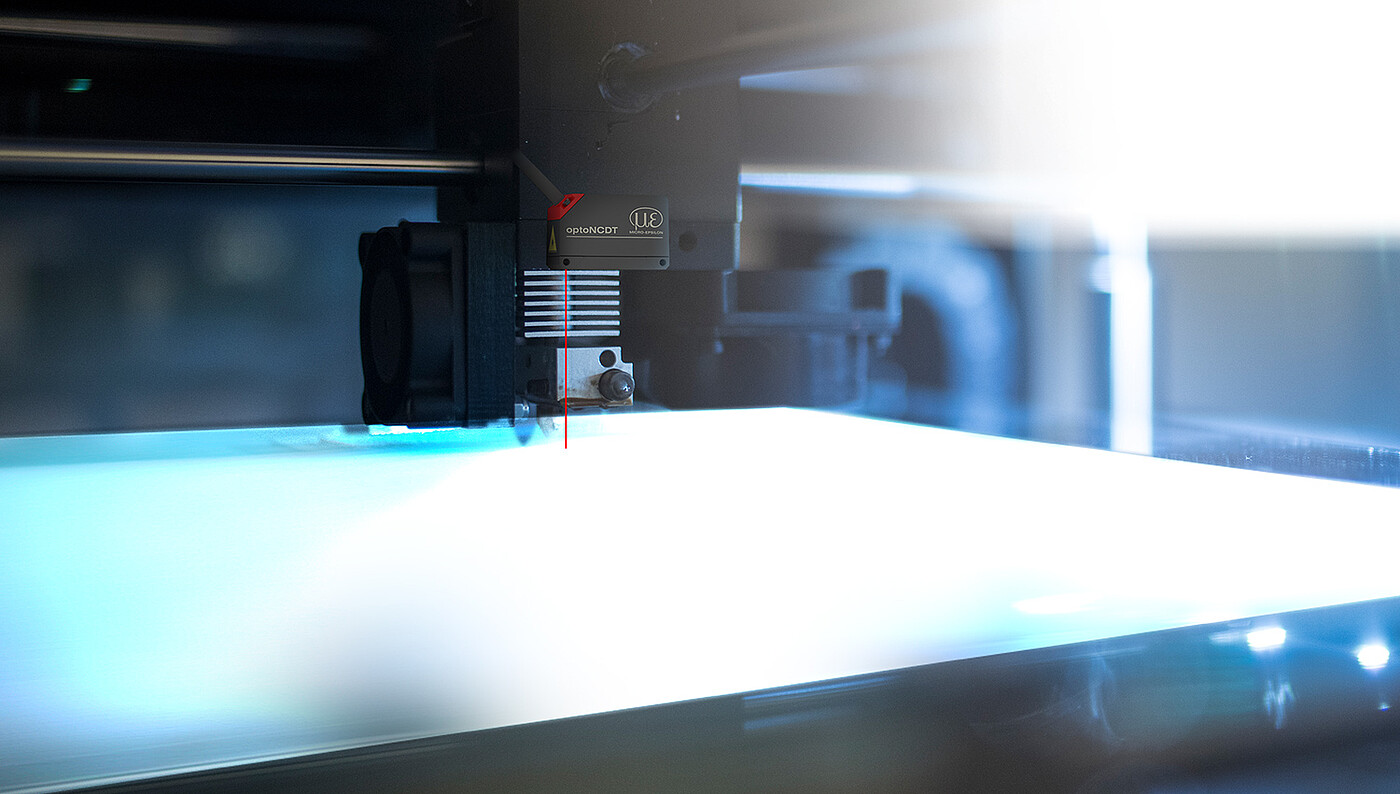

Laser sensors and laser triangulation sensors for maximum measurement accuracy

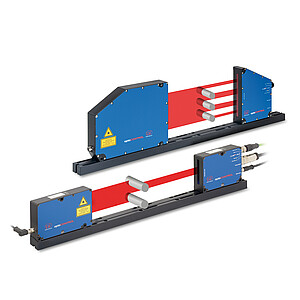

Laser sensors, especially laser triangulation sensors, are indispensable technologies for precise measurement applications in industry. These sensors provide accurate measurement data and enable precise distance and height measurements that are relevant for a wide range of industries - from the automotive industry and robotics to quality control and logistics.

What are laser triangulation sensors?

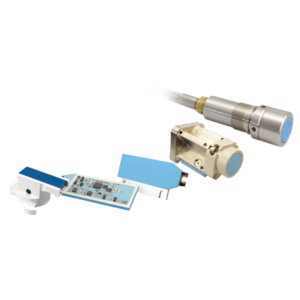

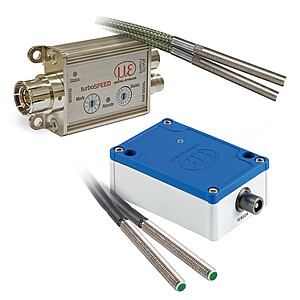

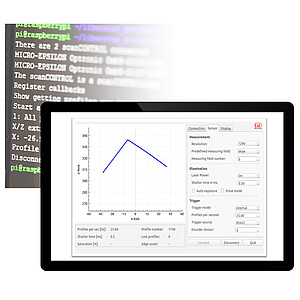

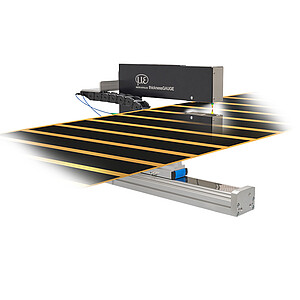

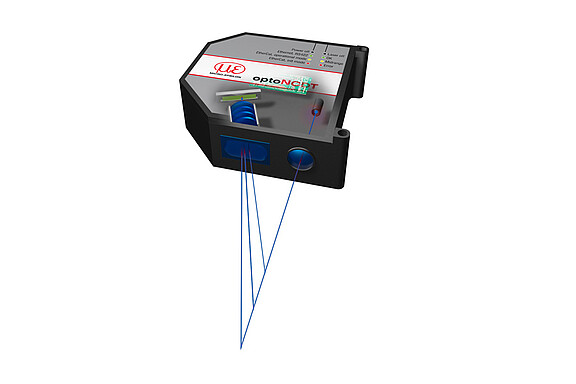

Laser triangulation sensors use the principle of laser triangulation to measure distances accurately. The sensor emits a laser beam onto the surface to be measured and the reflected beam is focused onto a receiver diode. The sensor calculates the distance based on the change of the angle of light - with an accuracy in the micrometer range.

Laserová triangulace - princip funkce senzorů

Triangulace znamená měření vzdálenosti pomocí výpočtu úhlu. Snímač promítá laserový bod na měřicí objekt. Odražené světlo dopadá na přijímací prvek pod určitým úhlem v závislosti na vzdálenosti. Z polohy světelného bodu na přijímači a vzdálenosti od vysílače k přijímacímu prvku se v senzoru vypočítá vzdálenost k měřicímu objektu.

Advantages of laser sensors and triangulation sensors:

- High measurement accuracy: Perfect for demanding applications.

- Robustness: Works reliably in industrial environments.

- Flexibility: Can be used on a wide range of surfaces and materials.

- Speed: Suitable for dynamic measurement processes.

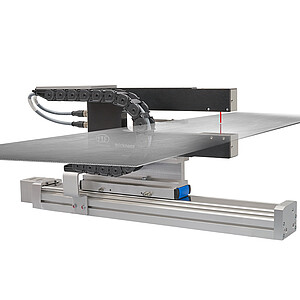

Applications and fields of use

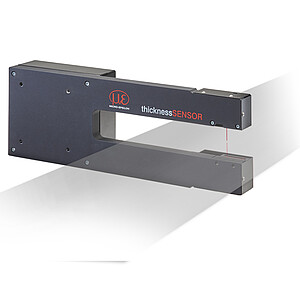

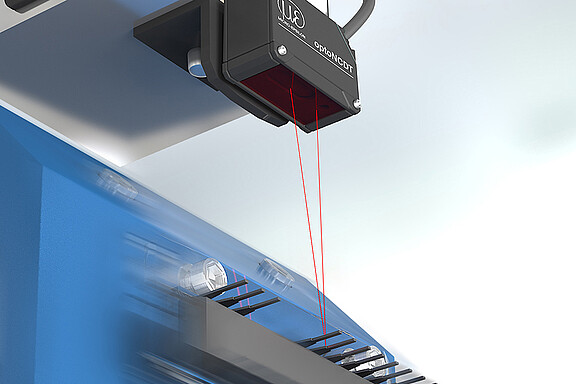

Laser sensors are used in numerous industries. Whether in quality control, where exact dimensions have to be determined, or in automated production lines, where fast and precise measurements are required - laser triangulation sensors are the solution. Application examples:

- Automotive industry: Measurement of vehicle parts for quality assurance.

- Medical technology: Application in highly sensitive measurement processes for medical devices.

- Robotics: Precise measurements enable exact robot positioning

- Machine building: Precise control and regulation of machines

- Automation: Detection of geometry deviations to ensure product quality.

Why laser sensors? Your advantages at a glance

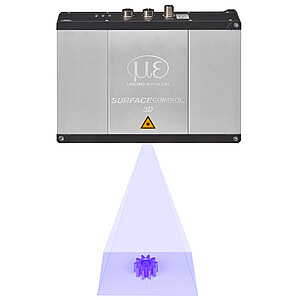

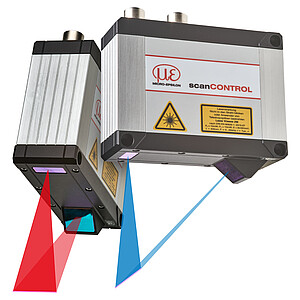

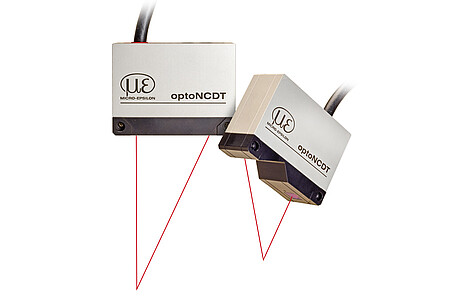

Laser triangulation sensors from Micro-Epsilon offer clear advantages over traditional measurement methods. Laser sensors from Micro-Epsilon provide long-time stable and precise measurements due to their advanced technology and robust design.

They enable non-contact measurement , which is particularly important for sensitive surfaces or dynamic processes. In addition, these sensors are able to react quickly to complex shapes and surfaces and thus provide data in real time.

FAQ

A laser triangulation sensor is a non-contact sensor for precise distance measurement. It projects a laser beam onto an object and a CMOS line detects the reflected beam at a specific angle. The sensor uses this angle to calculate the distance from the object - ideal for applications in quality assurance, automation and surface measurement. Equipped with high-quality components, laser sensors from Micro-Epsilon are extremely precise and suitable for fast measurements.

The precision of a laser sensor depends on several factors, including the surface quality of the measuring object, the ambient light conditions, the measuring range and the resolution. The high-quality triangulation sensors from Micro-Epsilon offer special filter and compensation functions to deliver accurate results even under difficult conditions.

Laser triangulation sensors are extremely precise, work without contact and are suitable for a wide range of materials and surfaces, even in fast production processes. They offer high measurement speed, are wear-free and provide reliable results, even in difficult lighting conditions. Another advantage is the large variety of measuring ranges - from a few millimeters up to 1 m measuring range can be realized with the laser triangulation sensors from Micro-Epsilon.

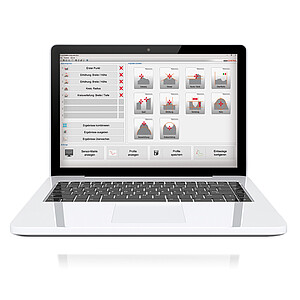

Why our laser sensors? - Advice and products for your requirements

Our customers appreciate our comprehensive technical support and fast delivery service. We offer the right laser sensor for your specific application needs. From consulting and selecting the right sensor to its integration into your systems - we offer quality and service at the highest level.

Get in touch with us to find out more about our innovative laser triangulation sensors and find the perfect solution for your measurement requirements.