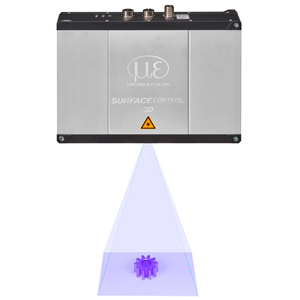

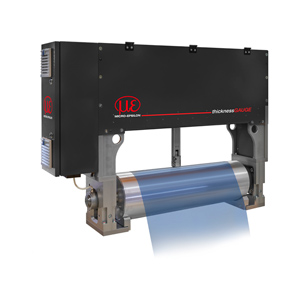

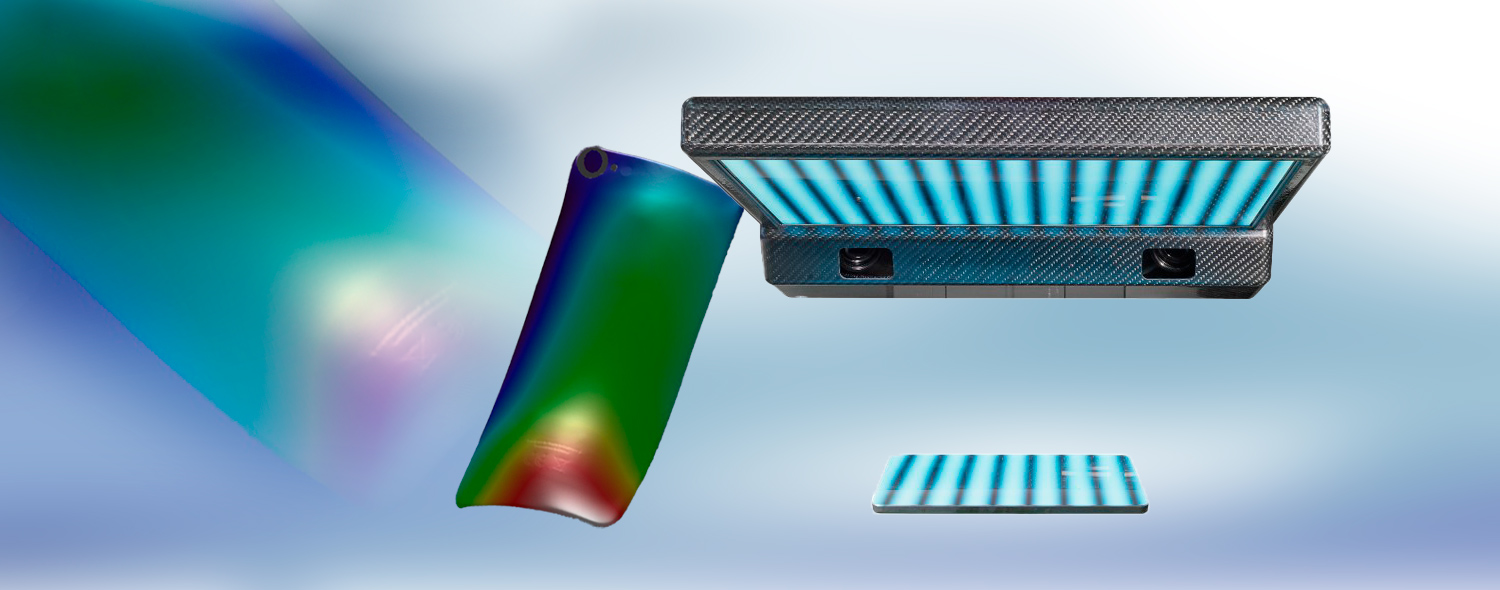

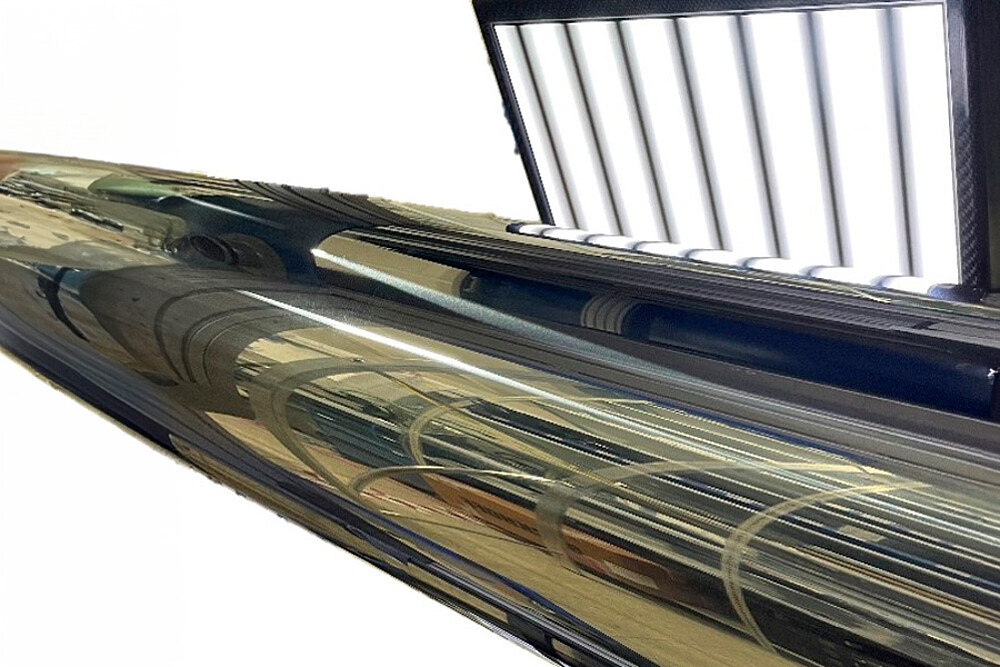

3D sensor for the measurement and inspection of shiny surfaces

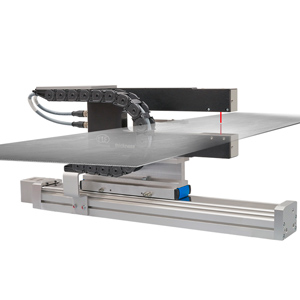

reflectCONTROL sensors offer an innovative solution for defect detection on highly reflective and transparent surfaces. These sensors use phase-measuring deflectometry and enable full-surface measurement. In contrast to conventional visual inspection by humans, which involves a great deal of manpower and working time, the reflectCONTROL sensor delivers precise measurement results that allow a detailed analysis of the surface quality. Powerful software packages are available for evaluation and parameterization, which significantly improve the efficiency and accuracy of surface inspection.

Characteristics

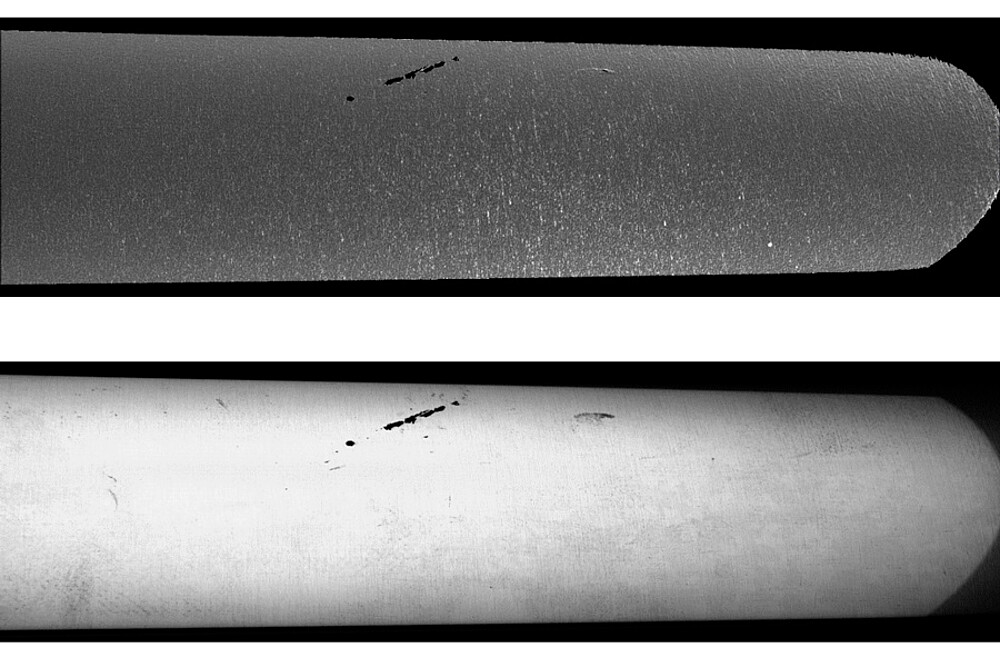

- Improved camera arrangement for sharper 2D images

- Even the smallest deviations from 10 nm can be detected

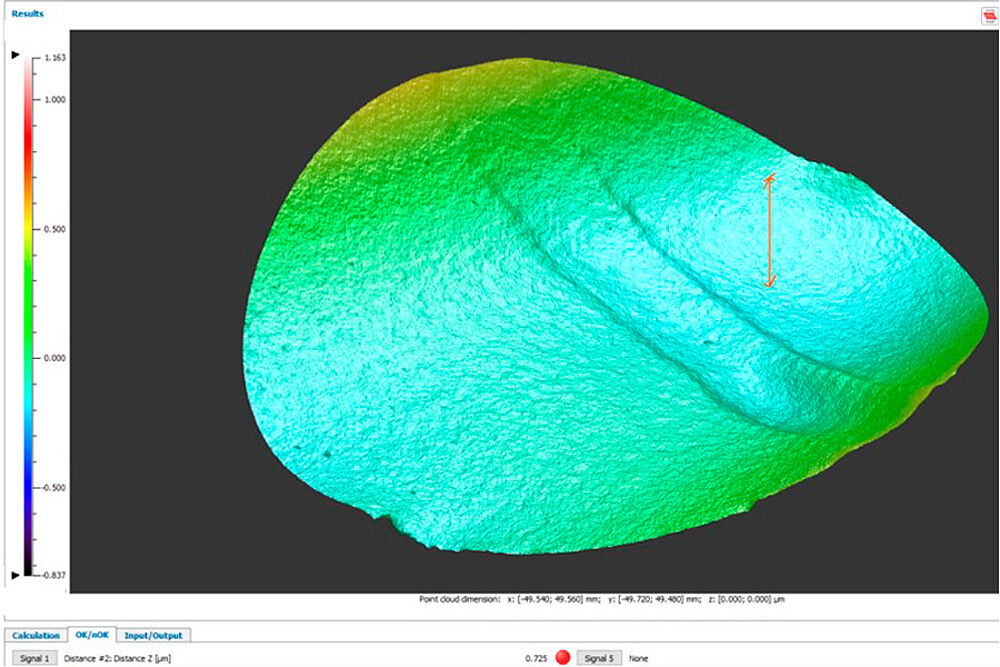

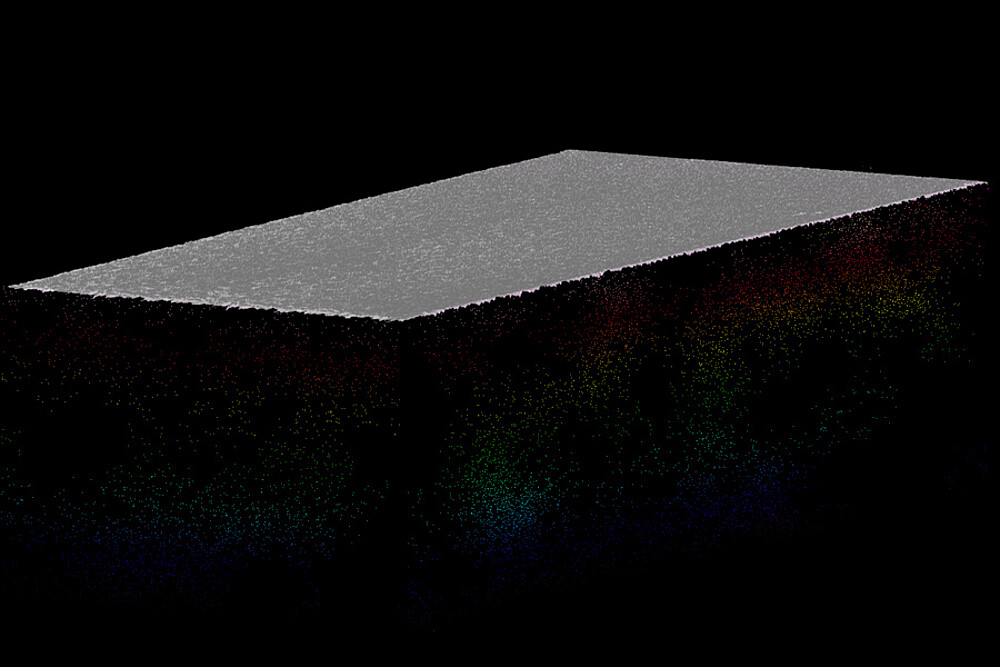

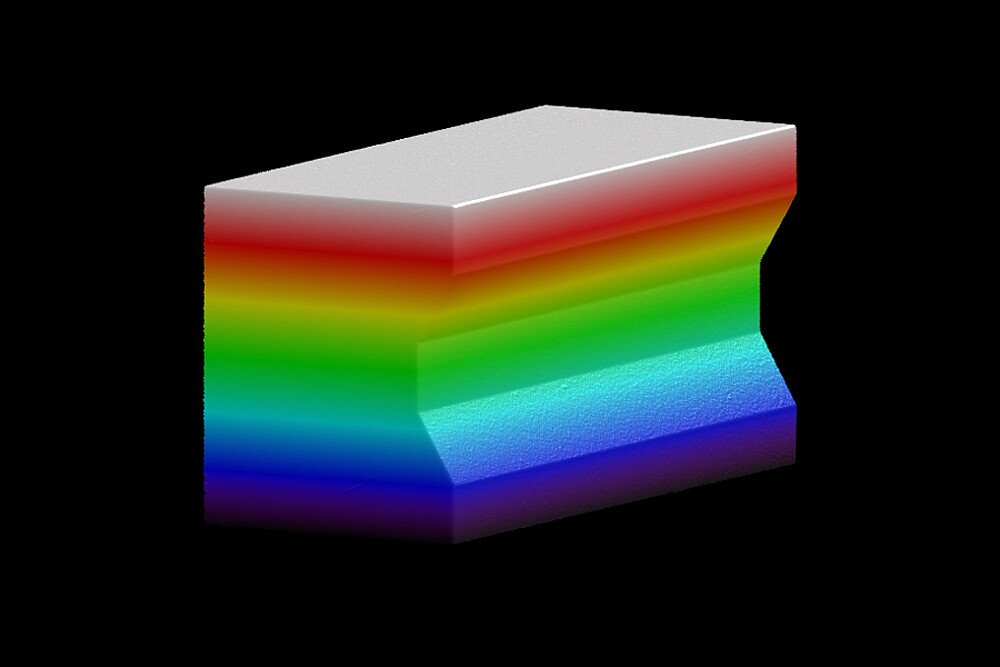

- Output of 3D point clouds for high-precision height measurement

- 3D data directly from the sensor with up to 5 million data points

- Resolution in the nanometer range in the Z-axis direction

- XY resolution 100 µm

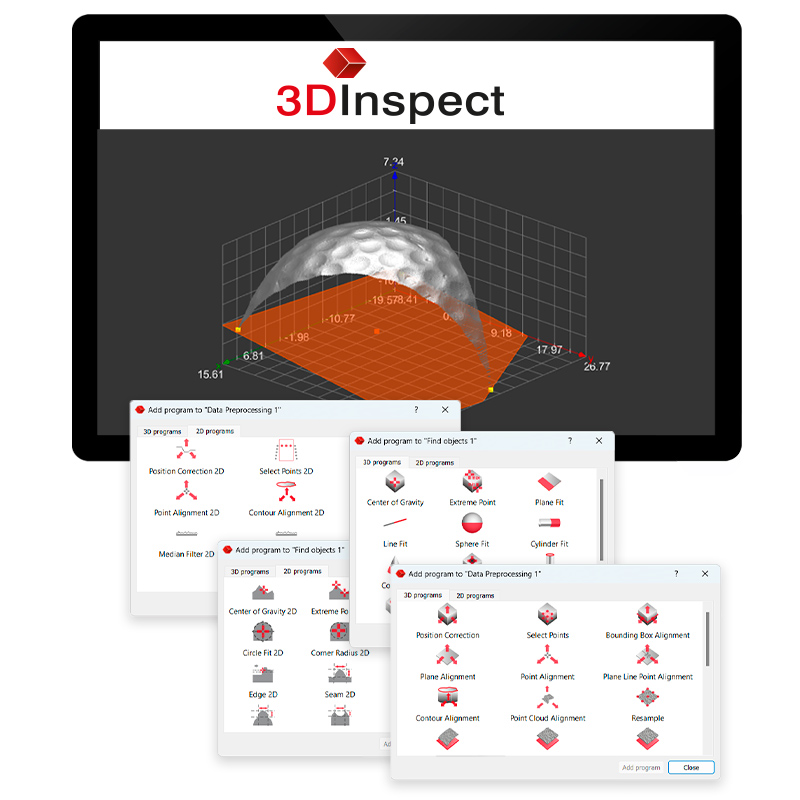

- Powerful 3DInspect software

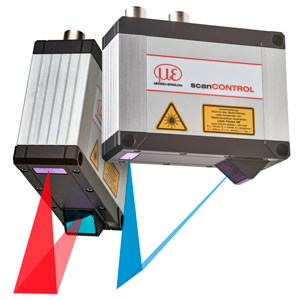

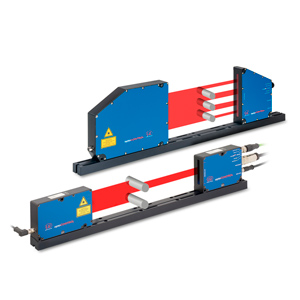

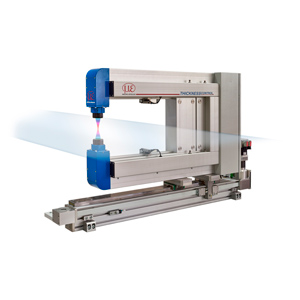

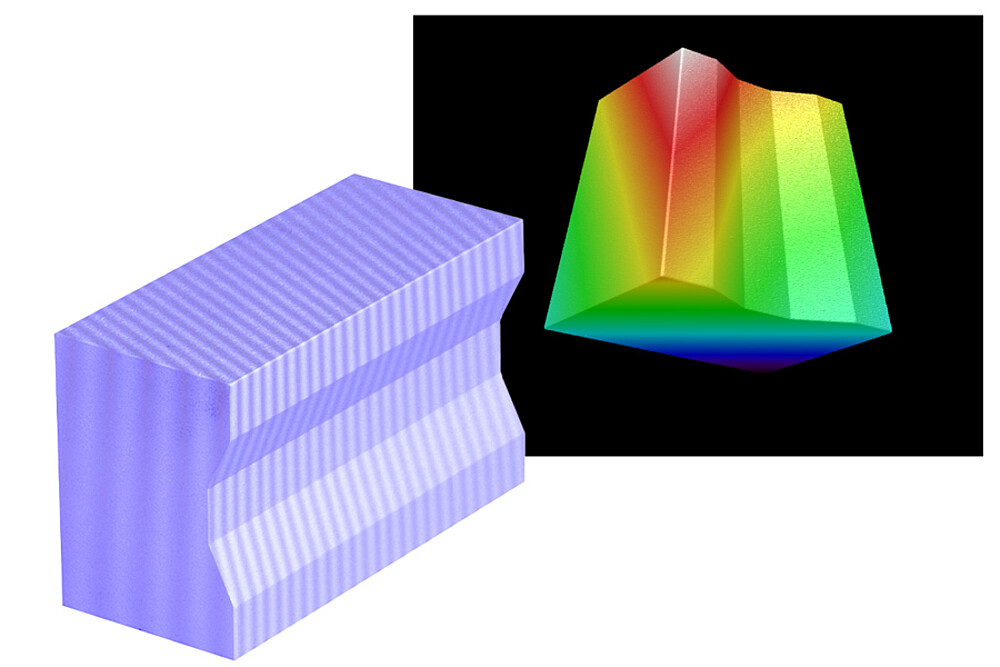

Deflectometry sensor for 3D measurements of shiny surfaces: RCS 130-160 3D HLP

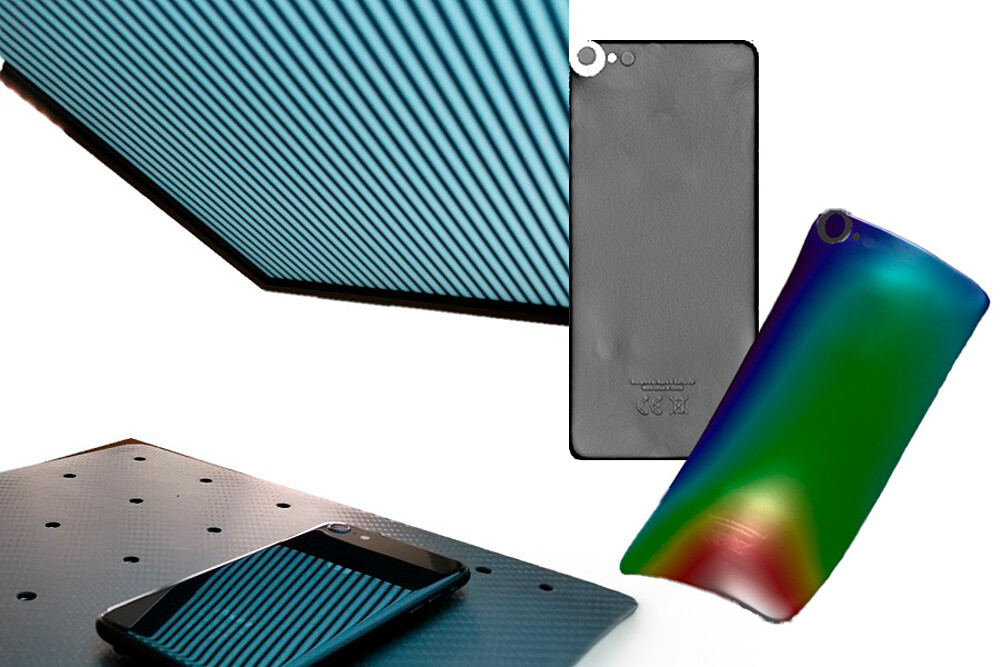

The RCS130-160 3D HLP is intended for shape measurements of shiny objects. This sensor displays a striped pattern which is mirrored by the surface of the measuring object into the sensor cameras. The sensor provides a 3D image of the surface which allows for the topology of the components (e.g. flatness, deflection, curvature) to be determined. The RCS130 model is specially optimized for measurement and inspection tasks, e.g., in production lines. Moreover, the sensor has a GigE Vision interface that offers GenICam compliant data.

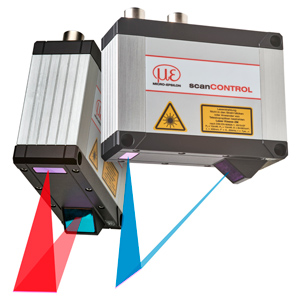

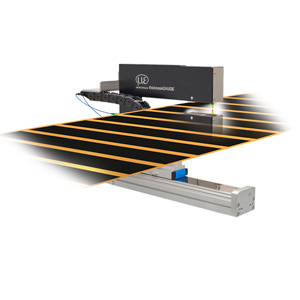

Surface inspection of shiny components: RCS 110-245 2D

The reflectCONTROL RCS110-245 2D with integrated controller is designed for stationary measurements or integration into machines. This compact sensor detects anomalies on shiny surfaces which are processed and displayed as reflectivity and curvature image by software. GigE Vision enables the transfer of surface images to a wide range of image processing software packages for further analyses.

Of course, all the functionalities of the RCS110-245 2D are also included in the reflectCONTROL RCS130-160 3D HLP. Both sensors therefore offer powerful solutions for surface inspection and enable seamless integration into existing systems.

Valid3D – Reliable 3D data

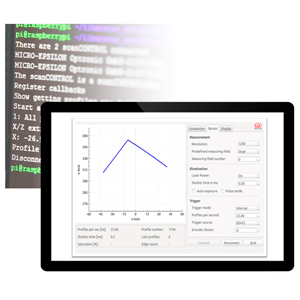

Softwarová integrace pomocí 3D-SDK od Micro-Epsilon

Snímač reflectCONTROL je vybaven sadou SDK (Software Development Kit) pro snadnou integraci. Sada SDK je založena na průmyslových standardech GigE Vision a GenICam, včetně následujících funkčních bloků:

- Konfigurace sítě a připojení senzoru

- Komplexní ovládání senzoru

- Kontrola přenosu obrazu

- Správa uživatelem definovaných sad parametrů

- C ++ ukázkové programy a dokumentace

Přístup k senzoru přes GigE Vision je také možný bez SDK, pokud máte klienta GenICam.