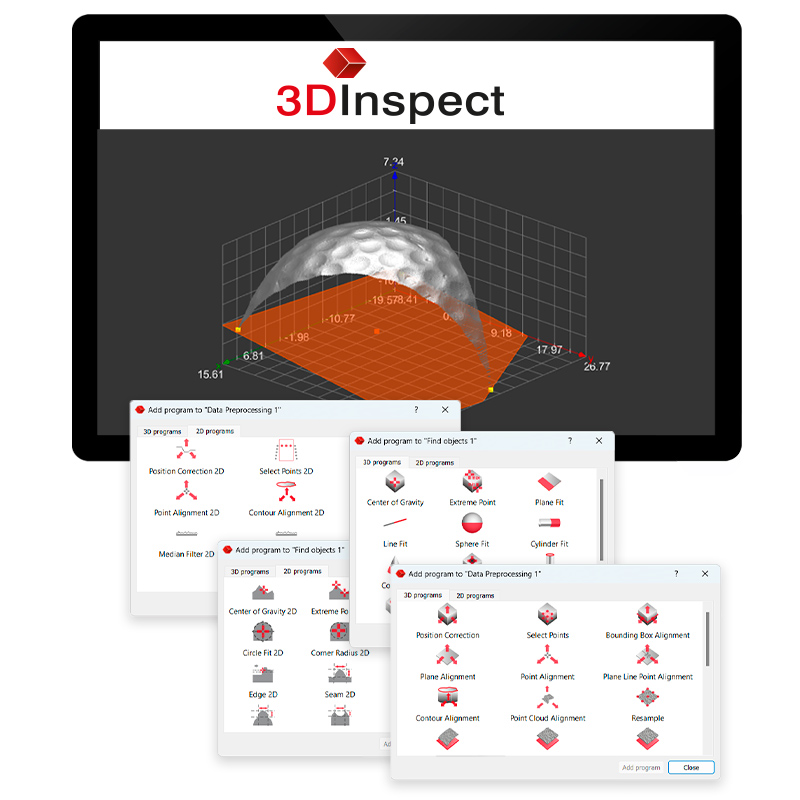

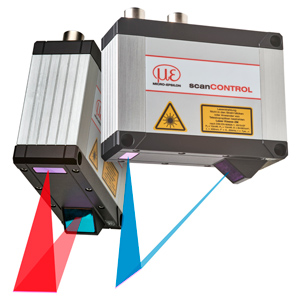

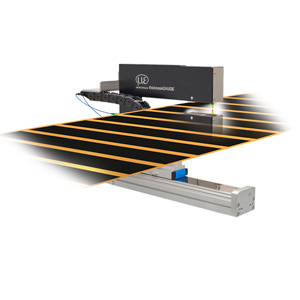

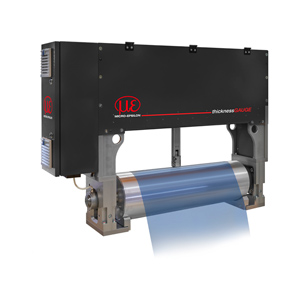

Polohování, rozpoznávání okrajů, naklopení, centrování

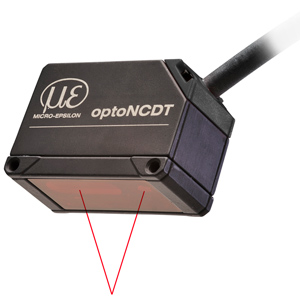

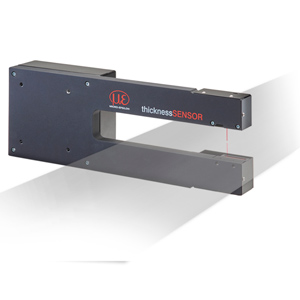

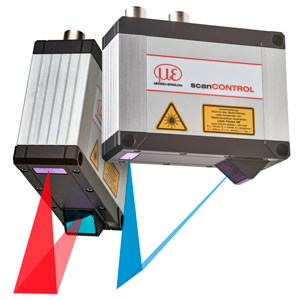

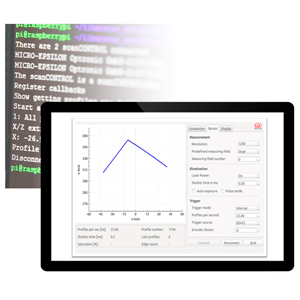

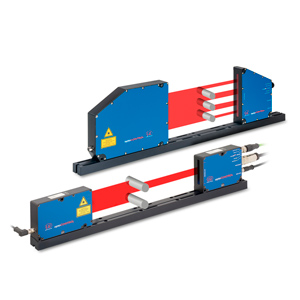

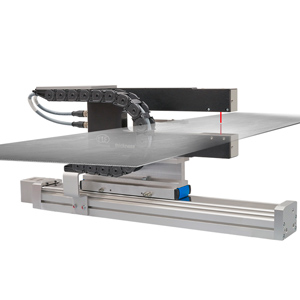

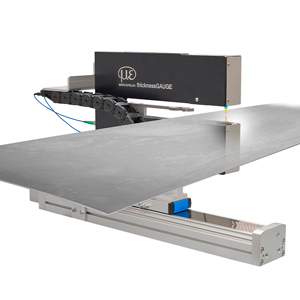

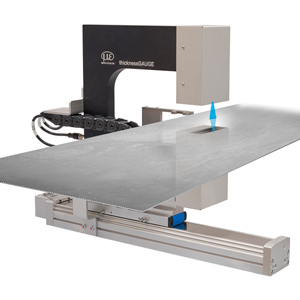

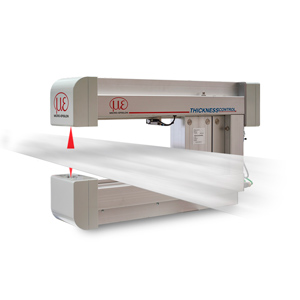

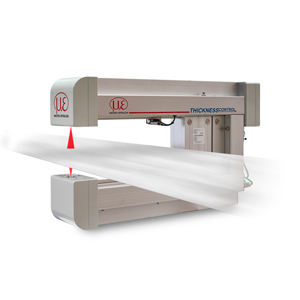

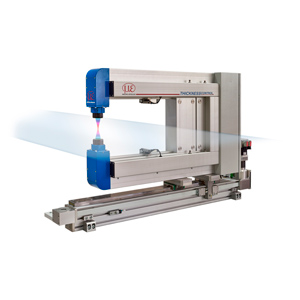

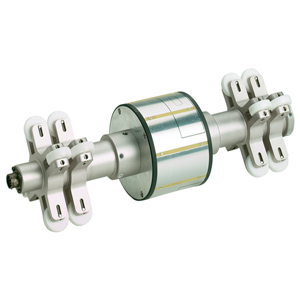

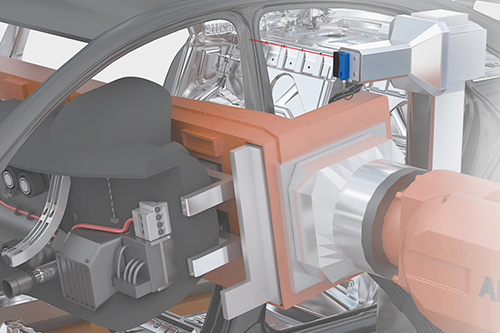

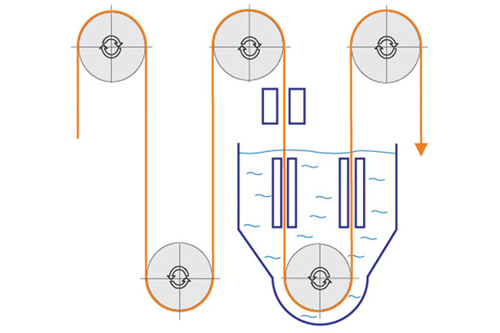

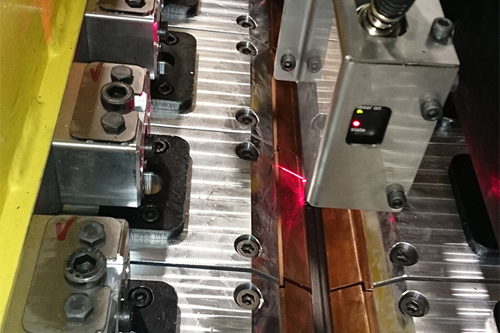

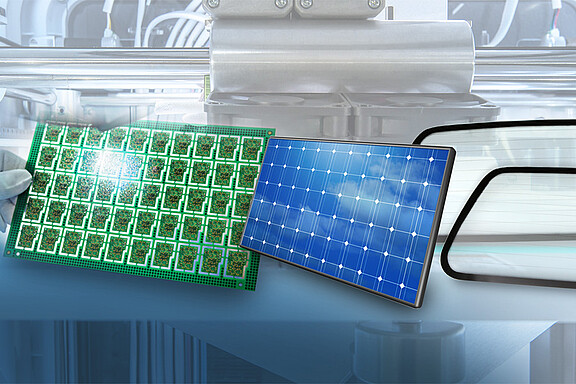

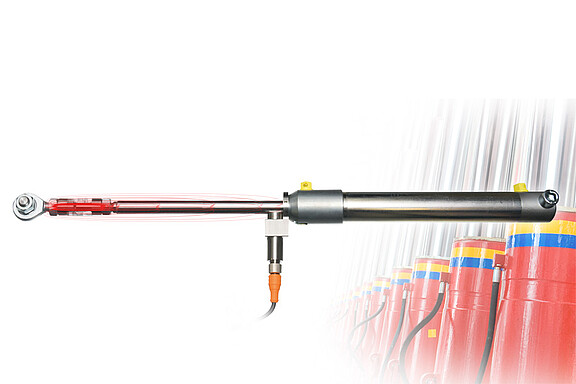

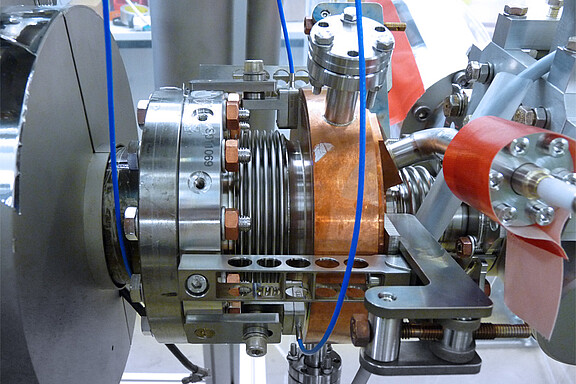

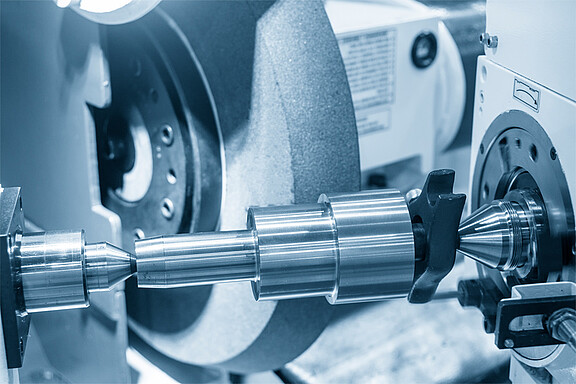

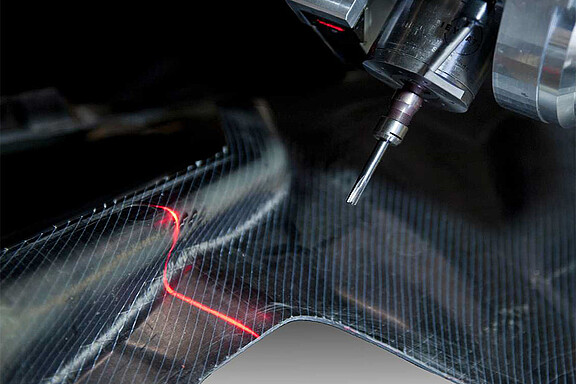

Různé části musí být často umístěny na určeném místě ve výrobních systémech nebo pro automatické pohyby. Tímto způsobem snímače mohou vysílat informace o vzdálenosti pouze kontroléru nebo provádět kompletní systémovou regulaci s jejich signály. Svařovací roboty s automatickým naváděním svarových spojů jsou příkladem automatické regulace. Používají se různé snímače v závislosti na tom, z jakého materiálu je vyrobena součást, která má být umístěna.