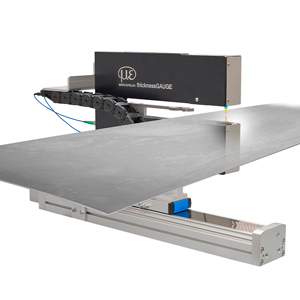

Measuring and inspection systems for the metal processing industry

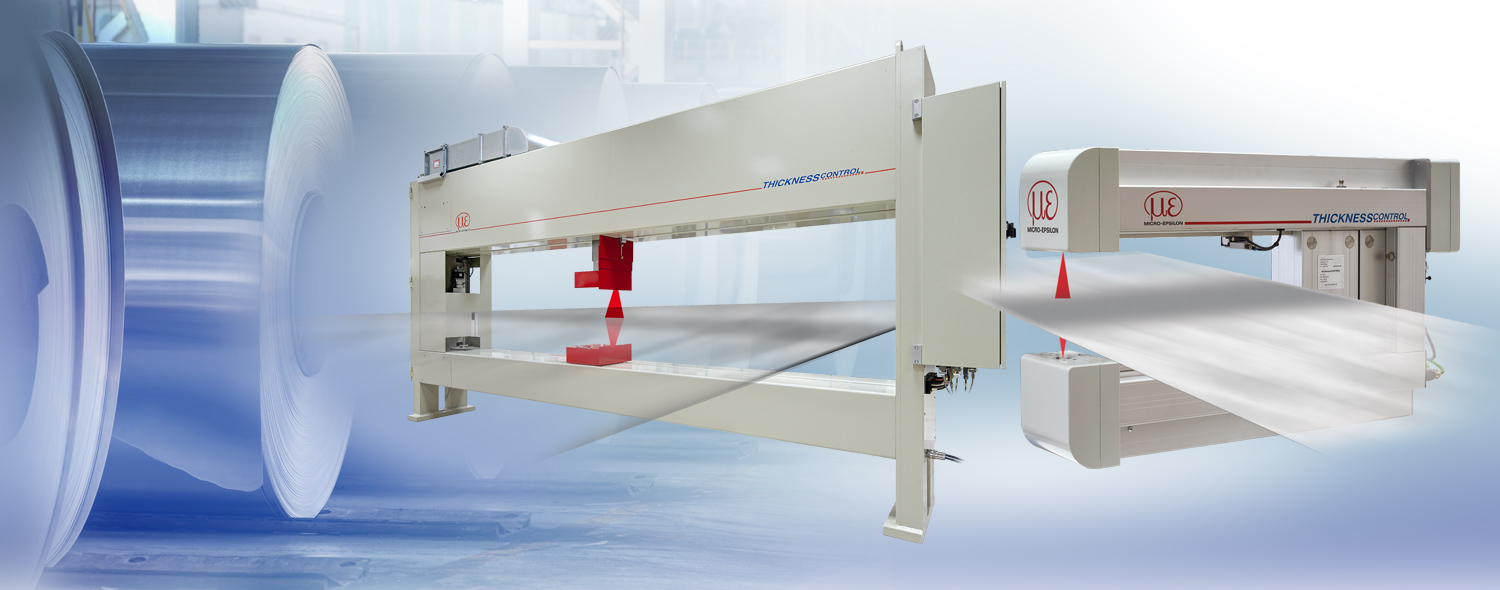

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry.

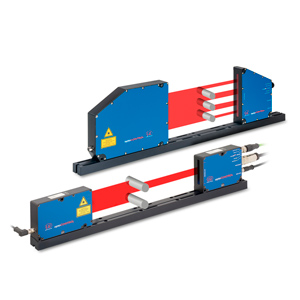

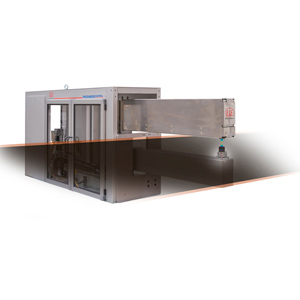

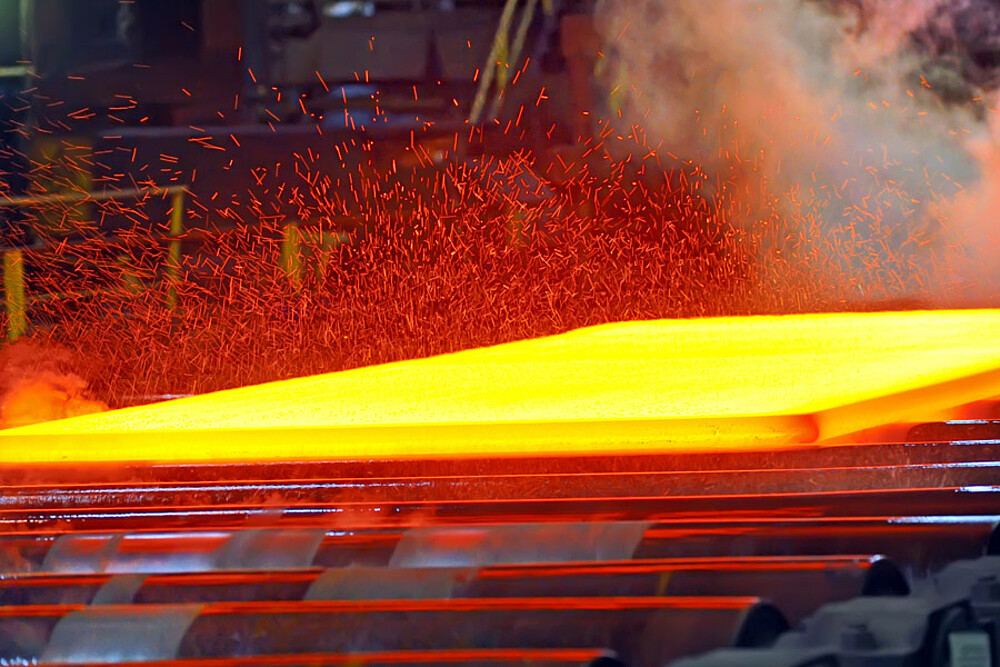

Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

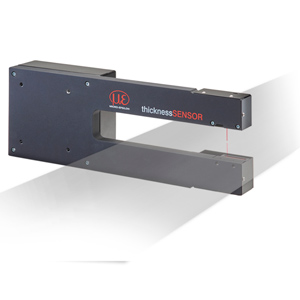

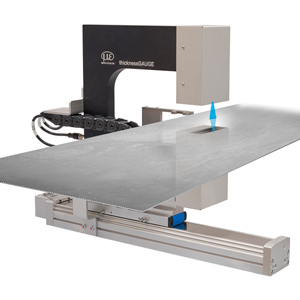

Princip měření tloušťky

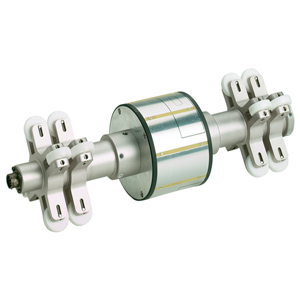

Princip rozměrového měření geometrické tloušťky zahrnuje jeden optický snímač vzdálenosti na každé straně materiálu. Vzdálenost (= provozní rozsah) obou snímačů je určena v kalibračním procesu založeném na certifikovaném měřicím standardu, jehož tloušťka je přidána ke součtu signálů snímače pro určení aktuálního provozního rozsahu. Pro měření tloušťky během výroby je určen rozdíl mezi součtem signálů vzdálenosti a hodnotou provozního rozsahu.

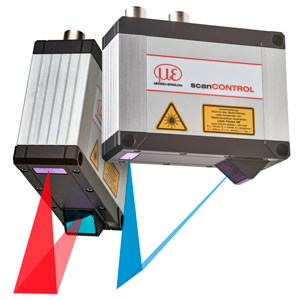

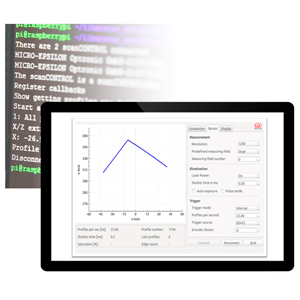

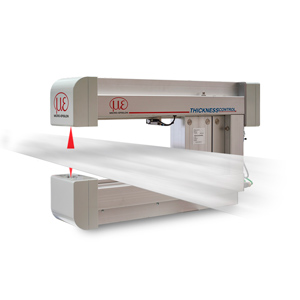

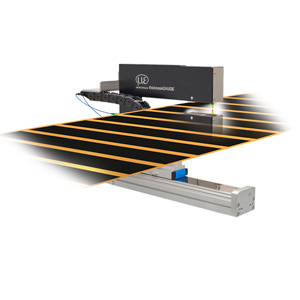

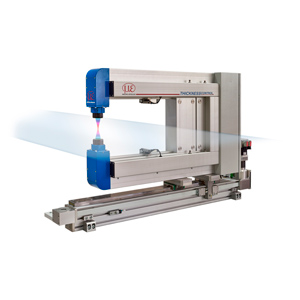

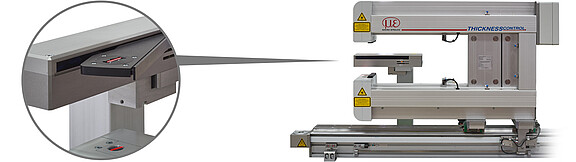

Leading role due to laser profile measurements

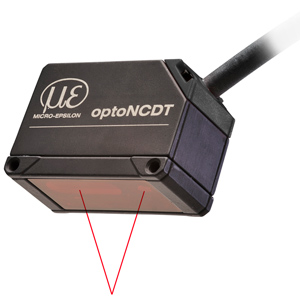

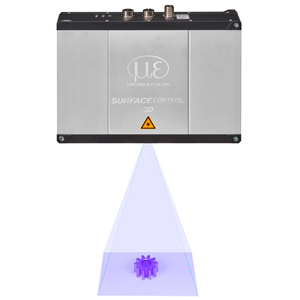

The thicknessCONTROL measuring systems can be equipped with different sensor technologies. In the aluminum and steel industry, laser profile scanners are the preferred choice with numerous advantages.

Advantages of laser profile sensors

- Environmentally friendly alternative to radiometric thickness measurement

- Free of isotope and X-ray radiation

- No consequential costs caused by hazardous waste

- No special safety measures (laser class 2)

- High measurement accuracy, even in harsh environments

- Large and small material thicknesses

- Independent of alloys, no specific calibration required

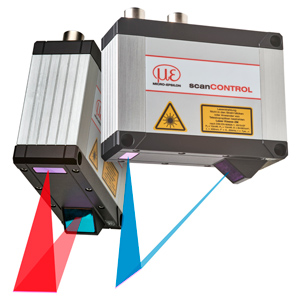

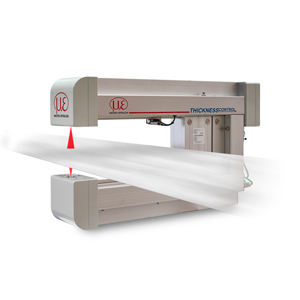

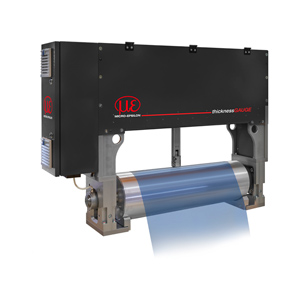

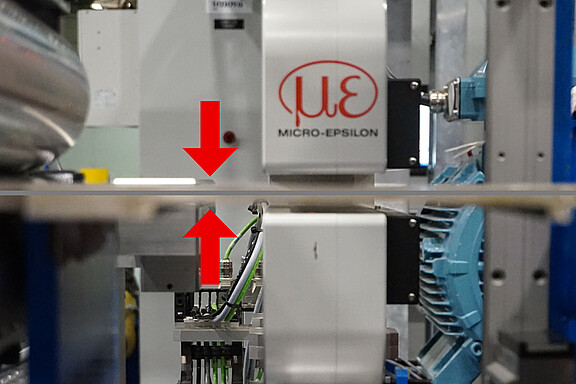

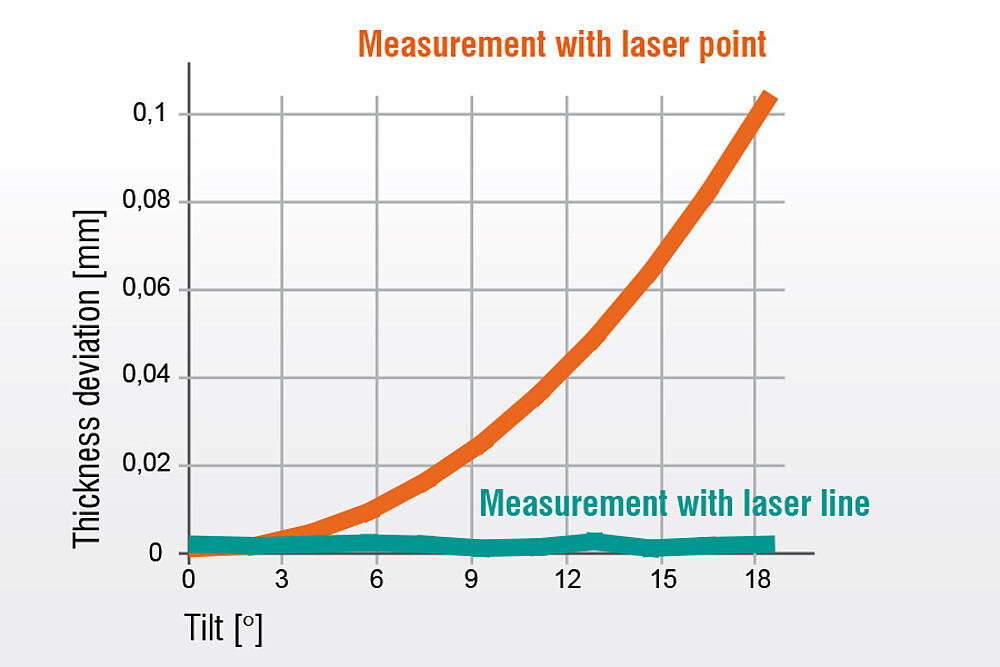

Inovace “samostatného laserového paprsku”

Použitím speciálních čoček se laserový paprsek zvětší tak, aby vytvořil statickou laserovou linii a promítne se na cílovou plochu. Vysoce kvalitní optický systém promítá difuzně odražené světlo této laserové linky na vysoce citlivý senzorový matrix, který v závislosti na snímači detekuje během jednoho měření profil s 640 nebo 1280 měřícími body. Z tohoto maticového obrazu vypočítá integrovaná řídící jednotka informace o vzdálenosti (osa z) a poloze podél laserové linie (osa x) ve dvourozměrném souřadném systému.

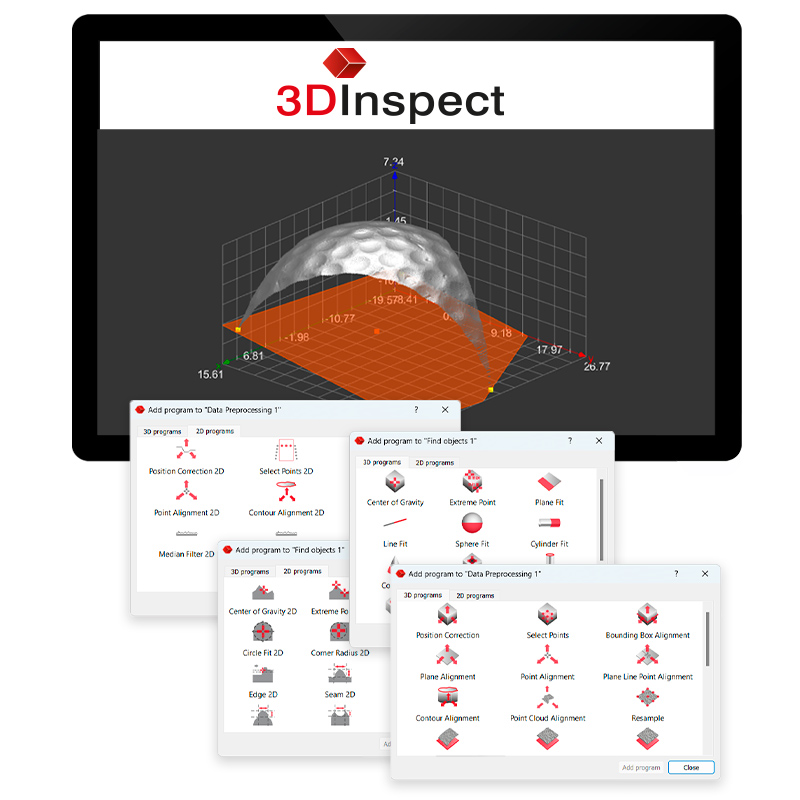

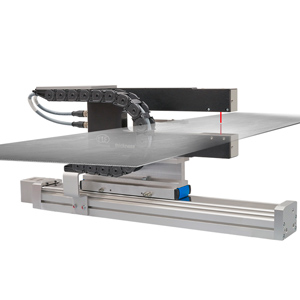

Automatická kalibrace

Systém je vybaven kalibrací in-situ, aby bylo možné kompenzovat např. účinky teplotních výkyvů. V závislosti na příslušné aplikaci lze s touto kalibrací umístit referenční/kalibrační kus nebo C-rám. Kromě toho může být kdykoli cyklicky prokázáno správné fungování systému. Analytický software umožňuje snadné a rychlé ověření schopnosti měřicího systému, které lze automatizovat v závislosti na aplikaci.