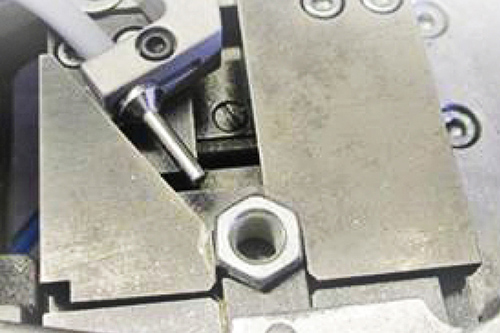

Recognizing color nuances and materials of screw nuts

For this measurement task, the controller is used together with the CFS3-A11 reflex sensor. Beforehand, the sensor is adjusted once to the brightest target, in this case a zinc nut. The nuts are transported on a vibrating conveyor and then pressed into a hexagonal shape by means of bolts. A screwdriver removes the nuts and places them in a holding mold. At this point of the process, the color inspection is carried out. The reflex sensor measures on the front faces of each nut, detects the color and performs an internal evaluation. Via digital outputs (0 V or 24 V) this evaluation can be output to a control system.

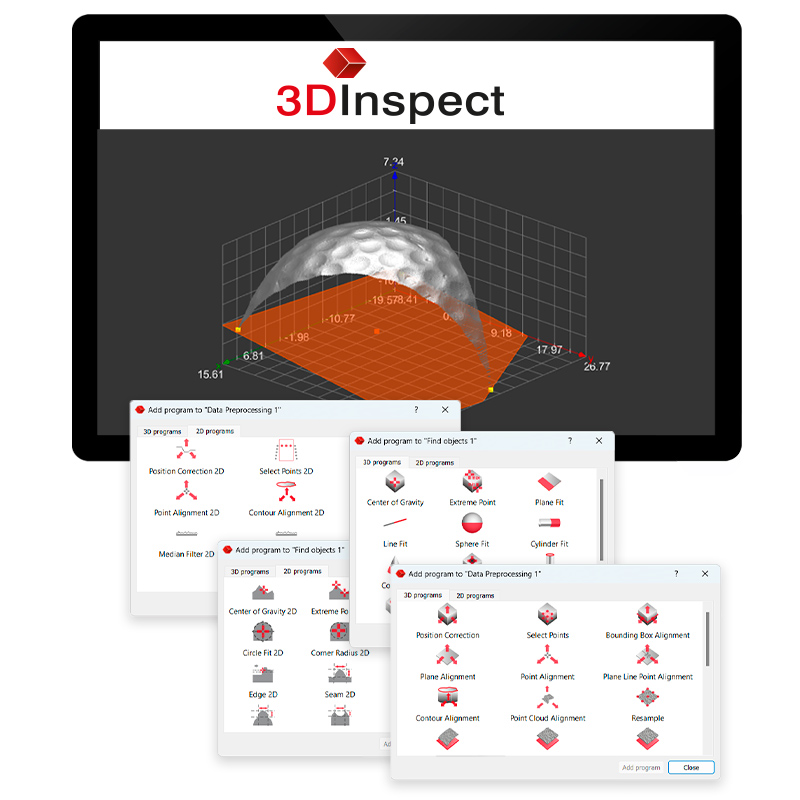

Up to 320 colors can be taught in 254 color groups. The colorSENSOR CFO achieves an extremely high recognition performance and process reliability. The web-based interface enables intuitive operation.