Measurement and monitoring of cannulas

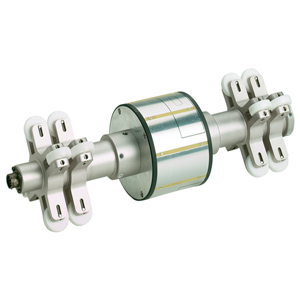

Cannulas, commonly recognized as LV needles, are hollow metal needles that are often attached to a plastic attachment, which is usually connected to a syringe. The end of a cannula usually has an angled cut to make a small incision when penetrating the tissue. The manufactoring of cannuals requires exact dimensional accuracy and precise alignment. Even the smallest deviations can cause unnecessary injury to the patient's tissue and promote bleeding or infection.

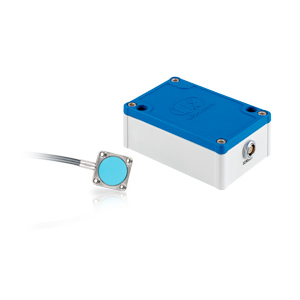

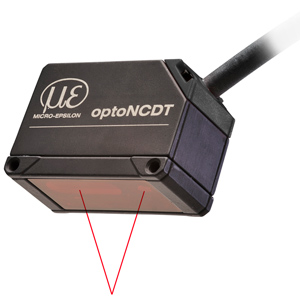

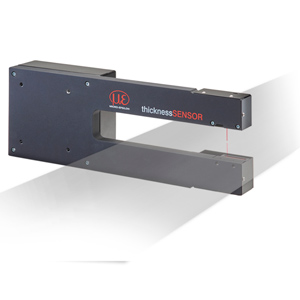

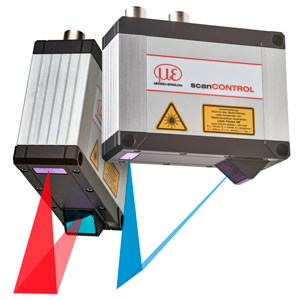

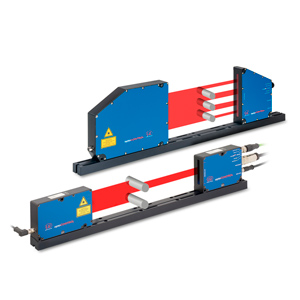

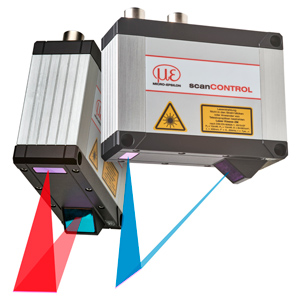

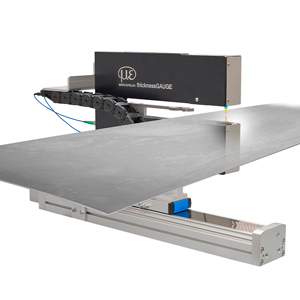

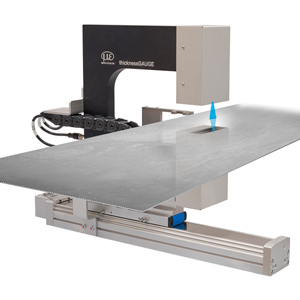

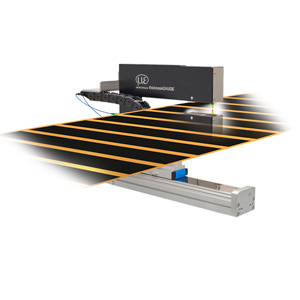

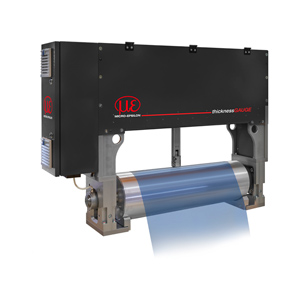

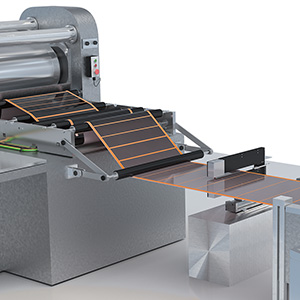

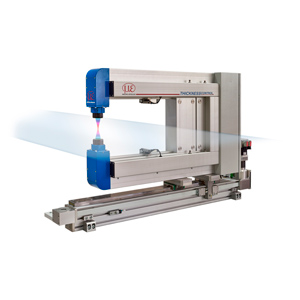

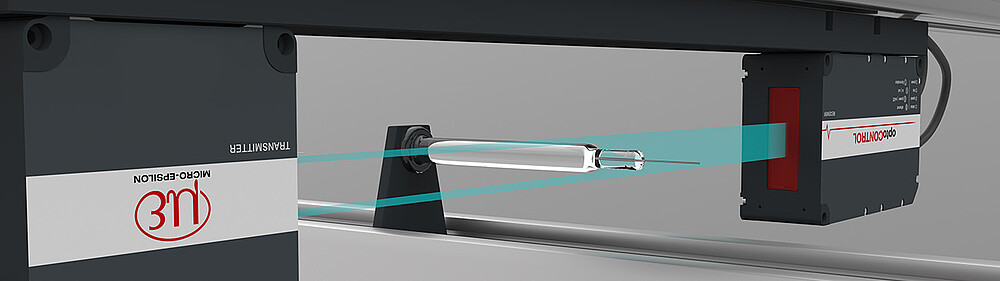

With the optoCONTROL 2700 from Micro-Epsilon, all relevant dimensions of cannulas can be measured inline and without contact. These include the outer diameter of the cannulas (gauge), the protrusion over the vitreous body and the tip geometry of the needle (angle, length and shape). This enables continuous quality control during the production process.

The optoCONTROL 2700 LED micrometer is available in two measuring ranges of 10 mm or 40 mm and can detect objects as small as 30 µm in diameter. The LED micrometer carries an impressive 10 nm resolution. This means that the optoCONTROL 2700 meets all the requirements for measuring even cannulas smaller than 33 gauge with an accuracy of 1 µm in accordance with ISO 9626. The protrusion of the cannula over the vitreous body can also be precisely determined thanks to the onboard "contour measurement" program.

The LED micrometer also detects the exact alignment and angle of the measuring object. Thanks to the active tilt correction, the measured value is adapted to the angle of the measured object in real time. This allows the alignment of the central axis of the glass body relative to the central axis of the cannula and the angle of the beveled needle tip to be determined.