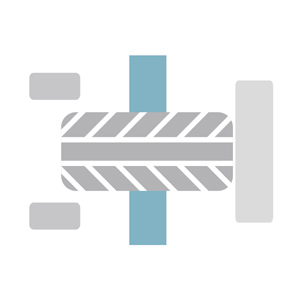

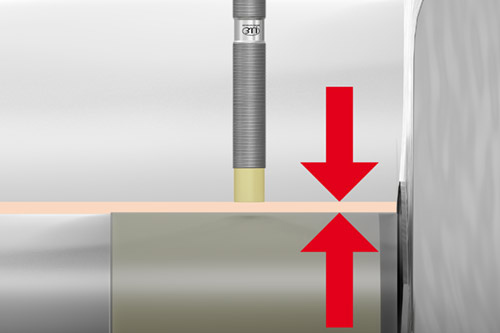

Measuring the bearing gap in axle bearings

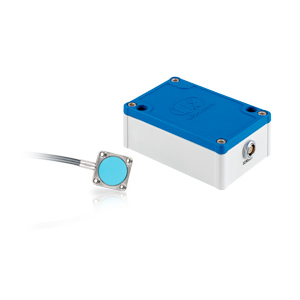

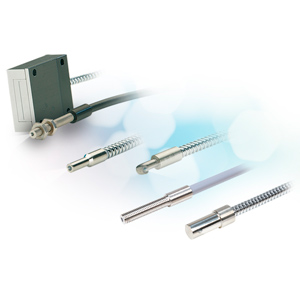

In high-speed trains, the oil gap in axle bearings is permanently checked. The oil film in the lubricating gap prevents direct contact between the bearing surface and the shaft. The improved sliding properties of the bearing increase the turbine’s effectiveness while prolonging its service life. eddyNCDT eddy current displacement sensors are used to monitor the bearing gap. Integrated into the control system, they acquire the measured values during operation. Thanks to their robust design, the sensors can be used at oil pressures of up to 2 bar and at high temperatures.