Measurement sensors for automation

Sensors play a vital role in automation technology. In addition to compact sizes, intelligent data processing and field bus connection, high performance is an increasingly common requirement for measurement technology. This is where the precise sensors from Micro-Epsilon come in: they can be used in a wide variety of applications, such as factory automation, autonomous assembly lines and complex process monitoring operations. The sensors provide highly precise measurement results to the master control unit. They impress with high integrability, performance and precision.

Why Micro-Epsilon?

Our sensors offer numerous advantages for the diverse requirements in the field of automation. These include robustness, accuracy and speed, as well as a high signal stability, a large temperature range and an attractive price-performance ratio.

- More precision and innovation – Made in Germany

- Intelligent sensors with high precision

- Hand in hand with our customers: quality and problem-solving expertise

- In-depth technological and practical knowledge in advanced automation

- Attractive price-performance ratio in series applications

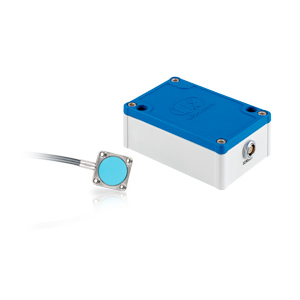

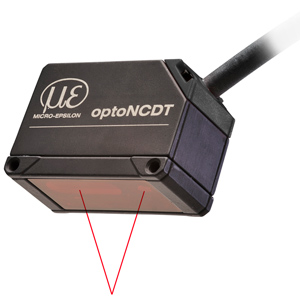

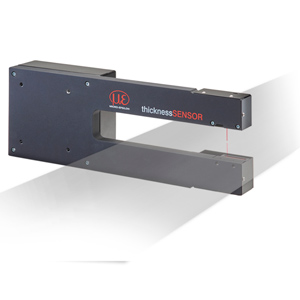

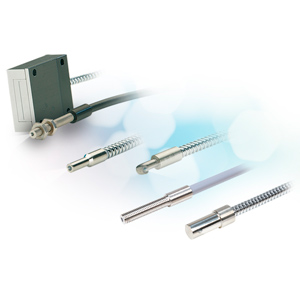

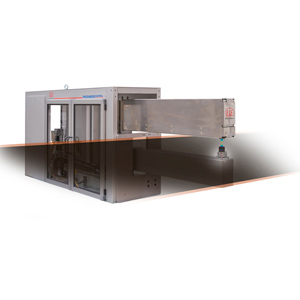

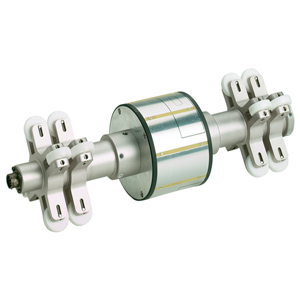

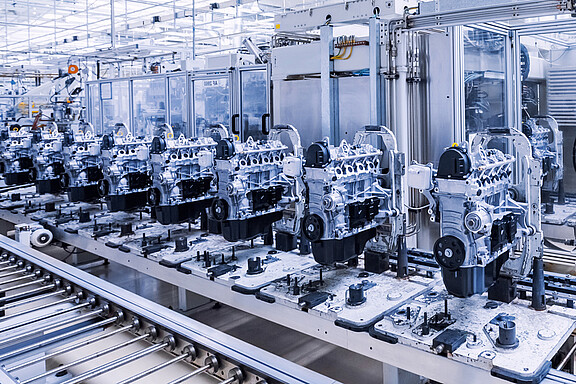

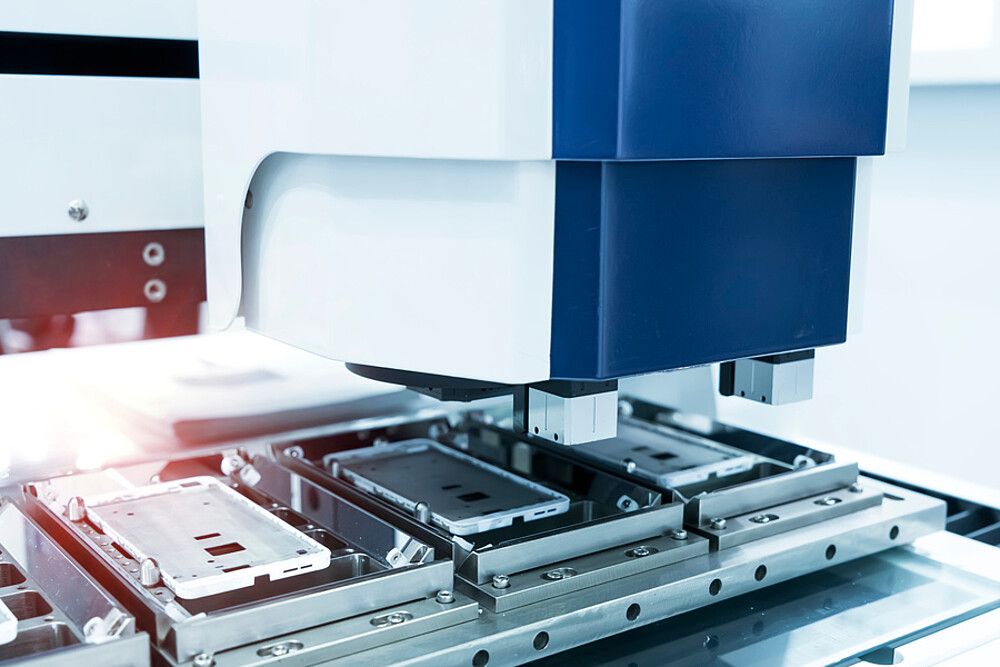

Reliable in series applications – sensors for factory automation

Processes and procedures are becoming ever more demanding in modern factory automation. Be it decentralization, stricter quality requirements or faster production cycles – sensors that provide more than just a switch signal are required. Our diverse range of sensor technologies hit the mark in factory automation applications and provide precise measurement results so that systems and processes can be reliably regulated. Whether on the production line or in robots, the sensors can be installed just about anywhere thanks to the variety of interfaces we offer.

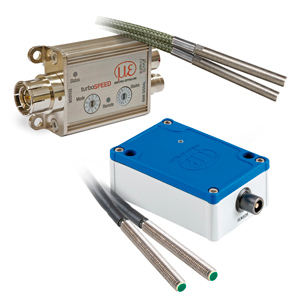

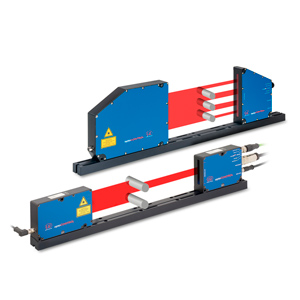

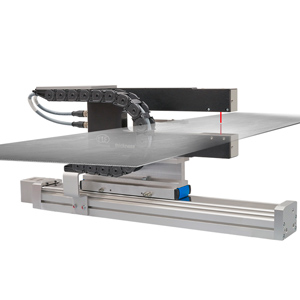

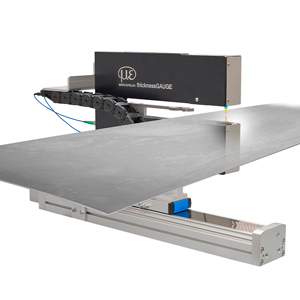

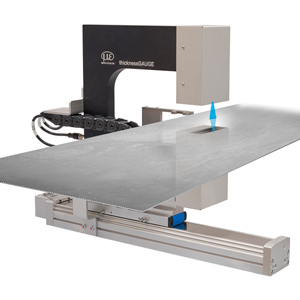

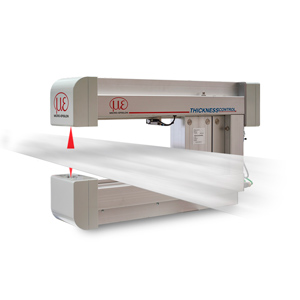

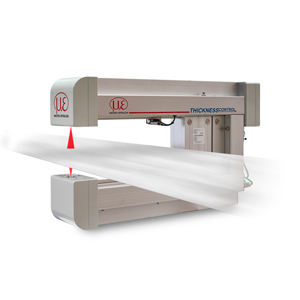

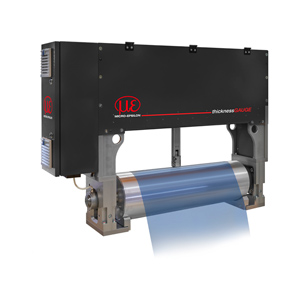

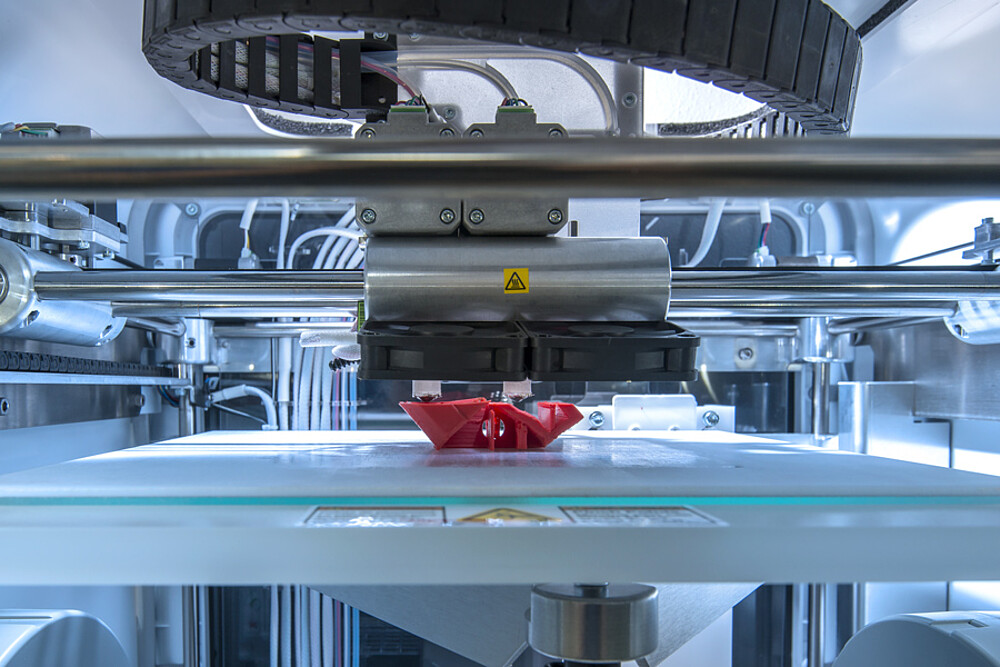

Sensors and systems for inline process monitoring

Competitivity in process automation is significantly improved by increasing efficiency. This involves networking processes, minimizing waste and optimizing throughput rates, among other things. Sensors and measuring systems from Micro-Epsilon also help with precise measurement data acquisition and integration in control systems. They check and monitor strip processes and continuous manufacturing processes with supreme accuracy.

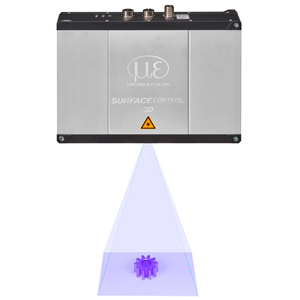

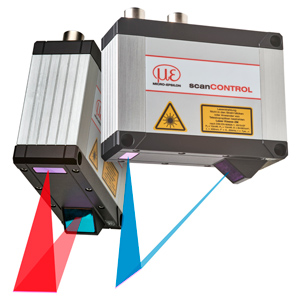

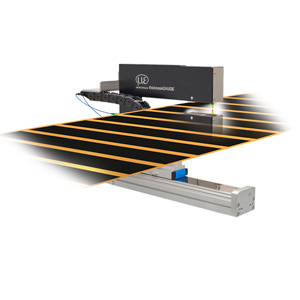

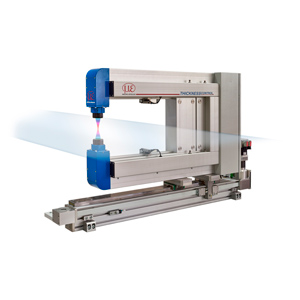

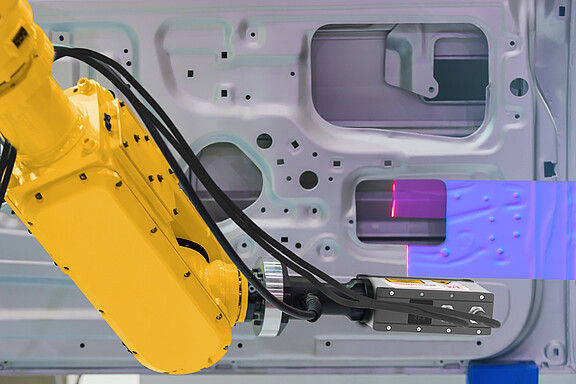

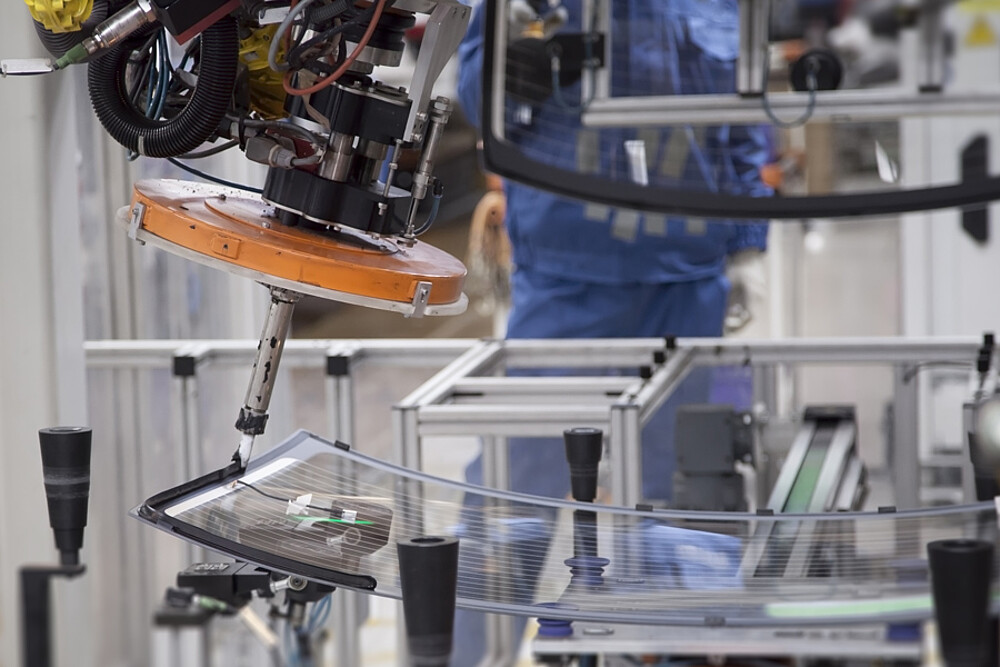

Inline manufacturing monitoring with 3D sensors

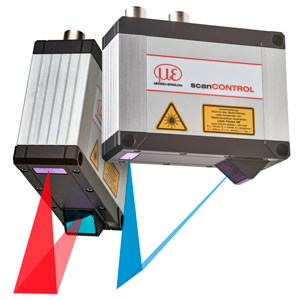

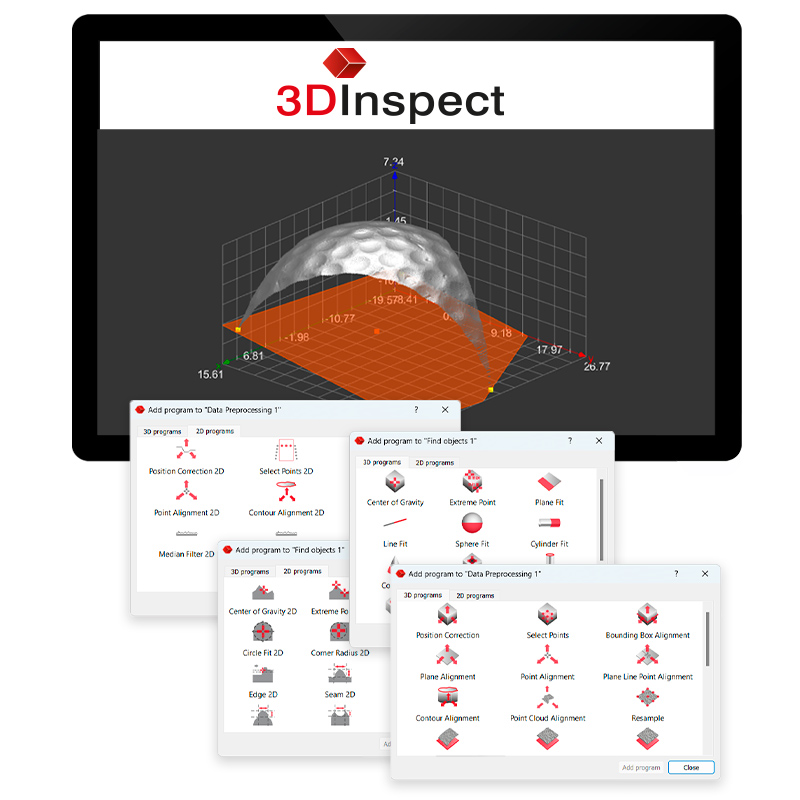

With the surfaceCONTROL, reflectCONTROL and scanCONTROL sensor systems, Micro-Epsilon presents a new generation of 3D sensors which are based on a common software platform. These 3D sensors are used for high-resolution geometry and surface measurements and detect the measuring object by scan or by single snapshot allowing fast inspection. Micro-Epsilon’s innovative Valid3D technology from Micro-Epsilon makes it possible to fully image and precisely evaluate the 3D point cloud. The 3D sensors are used for component shape inspection, position determination, presence inspection and flatness or planarity measurement. Thanks to their high level of performance, the sensors can be used for inline applications, on robots and for offline inspection.

- Inline use, on robots and offline inspection

- Complete 3D images in next to no time

- Snapshots that are accurate down to the last micrometer with simultaneously large measuring fields

- Simple integration in all widely used 3D image processing packages

- High-performance software for simple parameterization

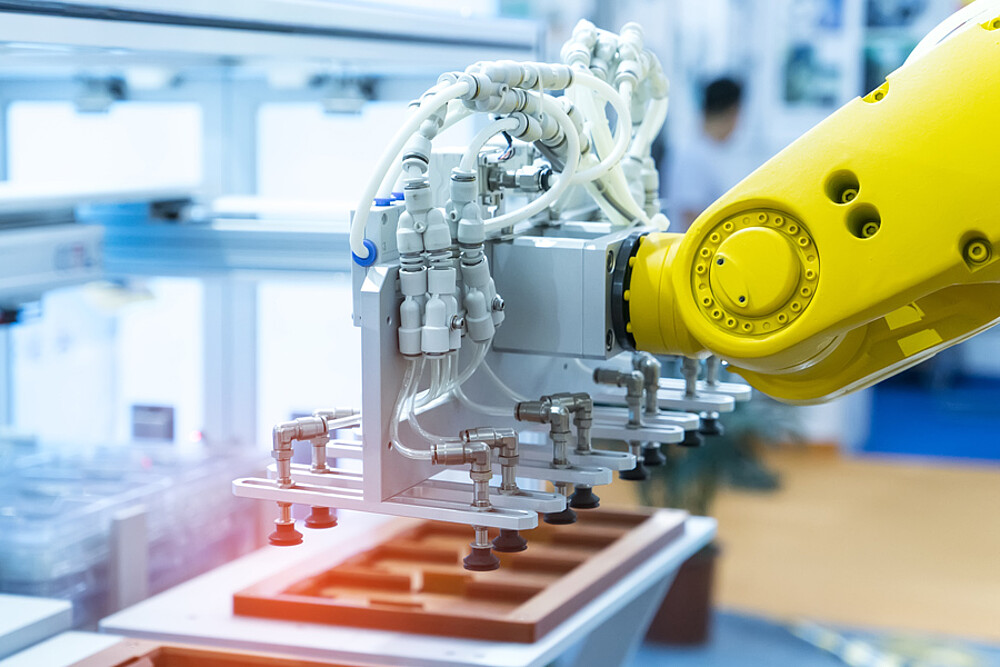

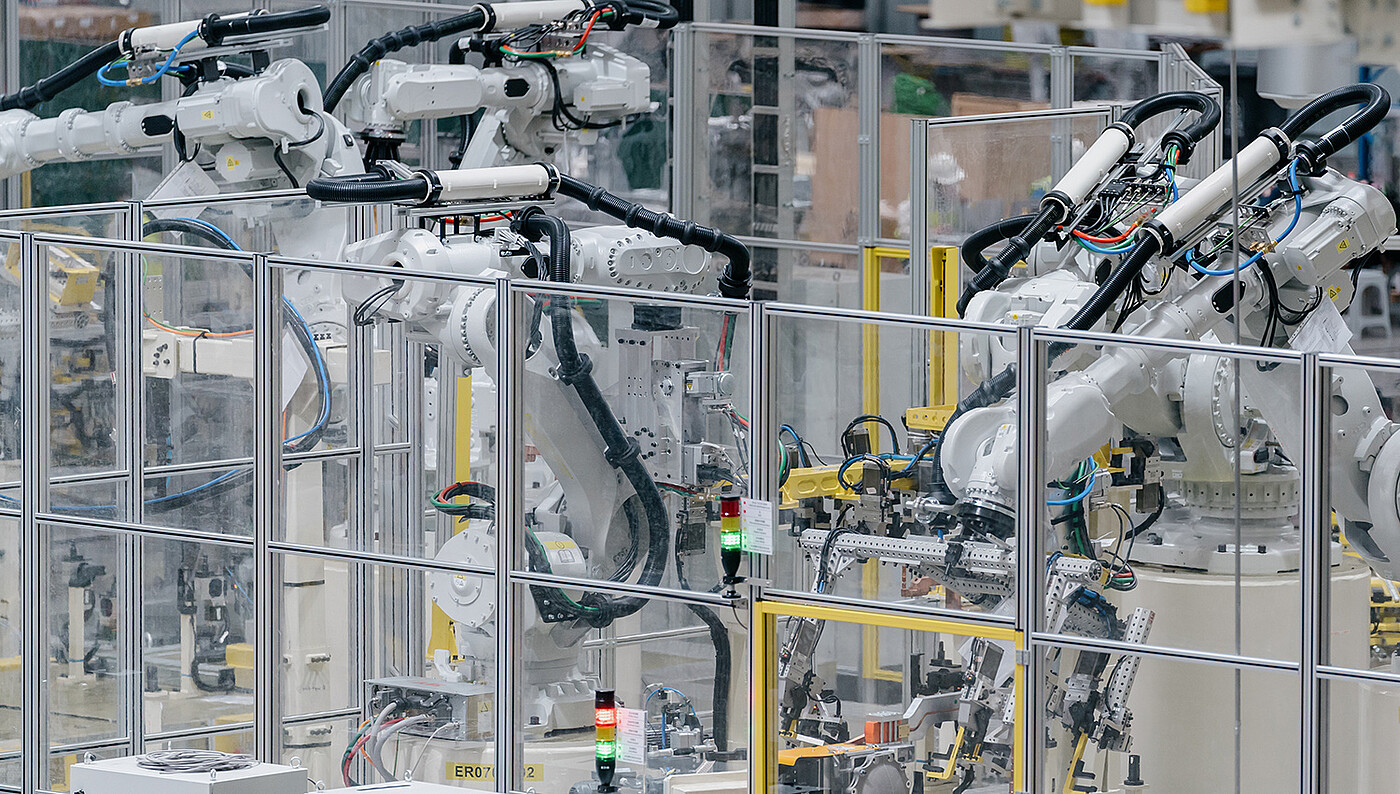

Sensors for Advanced Automation

Sensors from Micro-Epsilon make a decisive contribution towards quality improvement, cost reduction and resource savings in automation engineering. Micro-Epsilon offers a range of high-performance products as well as in-depth expertise for highly efficient sector and application solutions, in particular for series integration in inline manufacturing environments.

You can find application examples from automation engineering here

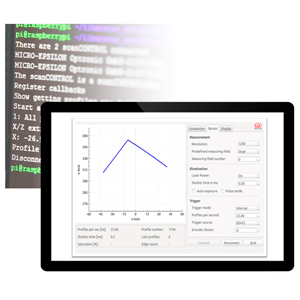

Multiple interfaces for easy integration