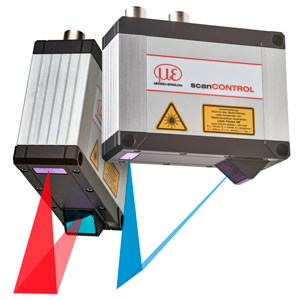

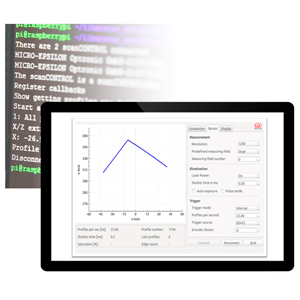

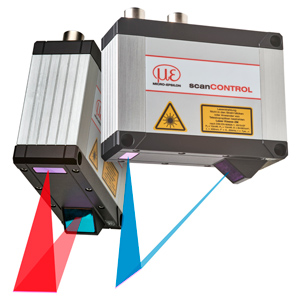

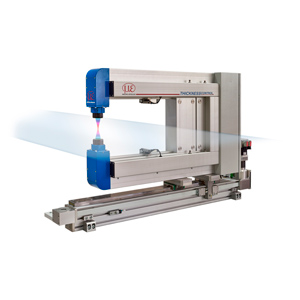

Micro-Epsilon scanCONTROL sensors are used for precise inline 3D measurement in numerous applications and industries. These versatile scanners are suitable for robotics applications and inline production monitoring, for example. Due to its design, a single laser scanner reaches its limits when detecting an entire circumference or entire geometries. However, if several sensors are strung together, a complete image of more complex geometries can be created.

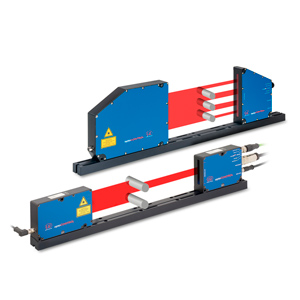

With the 3D Profile Unit, two laser scanners and their measured values can be combined to create an overall 2D profile or an overall 3D point cloud. The laser scanners are connected to the 3D Profile Unit via the Ethernet interfaces provided. Users can evaluate the profile data or 3D point clouds or forward them directly to a GigE Vision client. In the Industrial Ethernet option, measured values can also be output to the existing peripherals.

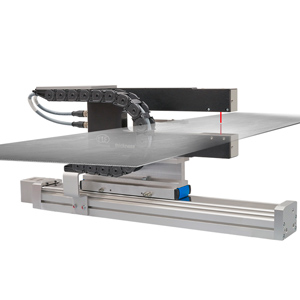

The hardware of the 3D Profile Unit with passive cooling offers flexibility for simple and space-saving installation. This simplifies integration in a control cabinet or mounting directly in the machine. The 3D Profile Unit for connects up to two sensors. The unit is designed according to IP40 and is insensitive to temperatures from 0 to +50 °C. It can be mounted on a table or wall.

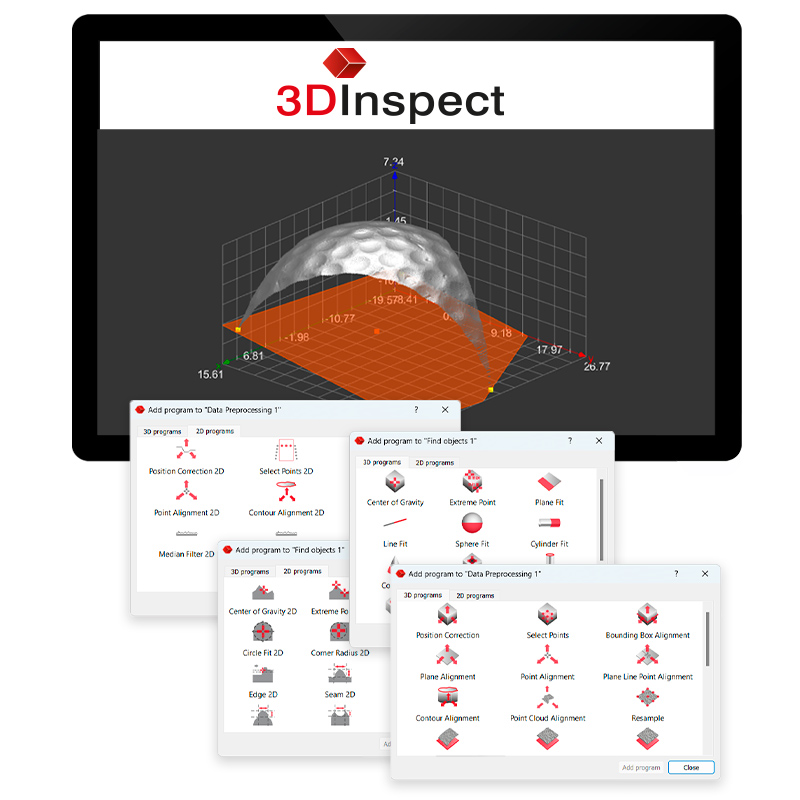

The 3D sensors are parameterized and the measurement data are acquired directly using the Micro-Epsilon 3D Inspect software. The strengths of the 3D Profile Unit can be harnessed in many different applications, such as in the measurement of power cables during stripping. Another application is the measurement of metal profiles, e.g. after extrusion. This involves a 3D measurement of the surface, which allows rejects to be identified and reduced.

- Snímače vzdialenosti

- Snímače vzdialenosti s vírivým prúdom

- Konfigurátor

- eddyNCDT 3001

![eddyNCDT 3001 Snímače vzdialenosti s vírivým prúdom]() Compact eddy current sensors with integrated controller

Compact eddy current sensors with integrated controller - eddyNCDT 3005

![eddyNCDT 3005 Snímače vzdialenosti s vírivým prúdom]() Miniature sensor system for integration into machines and systems

Miniature sensor system for integration into machines and systems - eddyNCDT 3060/3070

![eddyNCDT 3060/3070 Snímače vzdialenosti s vírivým prúdom]() High-performance sensor system for industrial applications

High-performance sensor system for industrial applications - eddyNCDT 3300

![eddyNCDT 3300 Snímače vzdialenosti s vírivým prúdom]() Ideal für schnelle Messaufgaben

Ideal für schnelle Messaufgaben - SGS 4701 Systém měření roztažnosti vřeten

![SGS 4701 Systém měření roztažnosti vřeten Snímače vzdialenosti s vírivým prúdom]()

- Špecifické senzory

![Špecifické senzory Snímače vzdialenosti s vírivým prúdom]()

- Kapacitné snímače vzdialenosti

- Konfigurátor

- capaNCDT 6110

![capaNCDT 6110 Kapacitné snímače vzdialenosti]() Ideal for industrial applications

Ideal for industrial applications - capaNCDT 61x0/IP

![capaNCDT 61x0/IP Kapacitné snímače vzdialenosti]() Robust design for industrial applications

Robust design for industrial applications - capaNCDT 61x4

![capaNCDT 61x4 Kapacitné snímače vzdialenosti]() Active measuring system for long cables

Active measuring system for long cables - capaNCDT 6200

![capaNCDT 6200 Kapacitné snímače vzdialenosti]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT 6228

![capaNCDT 6228 Kapacitné snímače vzdialenosti]() Ideal for high-temperature applications

Ideal for high-temperature applications - capaNCDT 6500

![capaNCDT 6500 Kapacitné snímače vzdialenosti]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT sensors

![capaNCDT sensors Kapacitné snímače vzdialenosti]()

- Customer-specific sensors

![Customer-specific sensors Kapacitné snímače vzdialenosti]()

- combiSENSOR

![combiSENSOR Kapacitné snímače vzdialenosti]()

- capaNCDT DTV

![capaNCDT DTV Kapacitné snímače vzdialenosti]()

- capaNCDT MD6-22

![capaNCDT MD6-22 Kapacitné snímače vzdialenosti]()

- capaNCDT TFG6220

![capaNCDT TFG6220 Kapacitné snímače vzdialenosti]() Thickness measurement of electrically conductive films

Thickness measurement of electrically conductive films

- Laserové snímače

- Konfigurátor

- optoNCDT 1220

![optoNCDT 1220 Laserové snímače]() Optimized for OEM and series use

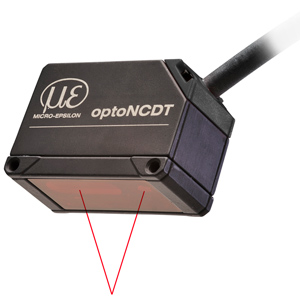

Optimized for OEM and series use - optoNCDT 1320

![optoNCDT 1320 Laserové snímače]() Compact design for precise measurements

Compact design for precise measurements - optoNCDT 1420

![optoNCDT 1420 Laserové snímače]() Smart laser sensor for precise measurements

Smart laser sensor for precise measurements - optoNCDT 1900

![optoNCDT 1900 Laserové snímače]() Innovative laser sensor for Advanced Automation

Innovative laser sensor for Advanced Automation - optoNCDT 2300

![optoNCDT 2300 Laserové snímače]() Highly dynamic laser sensor for precise measurements

Highly dynamic laser sensor for precise measurements - optoNCDT 5500

![optoNCDT 5500 Laserové snímače]() Vysoko výkonný laserový senzor pre špičkové aplikácie

Vysoko výkonný laserový senzor pre špičkové aplikácie - Snímače (verze BL) s modrým laserem

![Snímače (verze BL) s modrým laserem Laserové snímače]() Blue Laser sensor for metals and organic materials

Blue Laser sensor for metals and organic materials - Snímače s (LL) laserovou linkou

![Snímače s (LL) laserovou linkou Laserové snímače]() Ideal for shiny metallic and textured surfaces

Ideal for shiny metallic and textured surfaces - Snímače s velkým měřícím rozsahem

![Snímače s velkým měřícím rozsahem Laserové snímače]() Ideal for large measurement distances

Ideal for large measurement distances - Specifické laserové snímače

![Specifické laserové snímače Laserové snímače]()

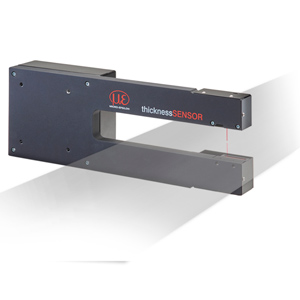

- thicknessSENSOR

![thicknessSENSOR Laserové snímače]()

- Konfokálne snímače

- Konfigurátor

- Konfokální sondy

![Konfokální sondy Konfokálne snímače]()

- confocalDT IFD2411

![confocalDT IFD2411 Konfokálne snímače]() Compact controller for series applications

Compact controller for series applications - confocalDT IFD2410/2415

![confocalDT IFD2410/2415 Konfokálne snímače]() Compact sensors with integrated controller

Compact sensors with integrated controller - confocalDT IFC2411

![confocalDT IFC2411 Konfokálne snímače]() Compact single-channel controller for industrial series applications

Compact single-channel controller for industrial series applications - confocalDT IFC2416

![confocalDT IFC2416 Konfokálne snímače]() Compact single-channel controller for industrial series applications

Compact single-channel controller for industrial series applications - confocalDT IFC2421/22

![confocalDT IFC2421/22 Konfokálne snímače]() Single or dual-channel controller for industrial applications

Single or dual-channel controller for industrial applications - confocalDT IFC2465/66

![confocalDT IFC2465/66 Konfokálne snímače]() One / two-channel controller for fast & precise measurements

One / two-channel controller for fast & precise measurements - Accessories

- Interferometers (white light)

- interferoMETER 5200-TH

![interferoMETER 5200-TH Interferometers (white light)]() Reliable inline measurement of thin layers

Reliable inline measurement of thin layers - interferoMETER 5400-DS

![interferoMETER 5400-DS Interferometers (white light)]() Absolute distance measurement with nanometer accuracy

Absolute distance measurement with nanometer accuracy - interferoMETER 5400-TH

![interferoMETER 5400-TH Interferometers (white light)]() Stable thickness measurement with submicrometer accuracy

Stable thickness measurement with submicrometer accuracy - interferoMETER 5600-DS

![interferoMETER 5600-DS Interferometers (white light)]() Absolute distance measurement with subnanometer accuracy

Absolute distance measurement with subnanometer accuracy - interferoMETER 5420-TH

![interferoMETER 5420-TH Interferometers (white light)]() High-precision thickness measurement of SI wafers

High-precision thickness measurement of SI wafers

- interferoMETER 5200-TH

- Optické diaľkomery

- optoNCDT ILR1030/1031

![optoNCDT ILR1030/1031 Optické diaľkomery]() Compact laser distance sensors

Compact laser distance sensors - optoNCDT ILR1171

![optoNCDT ILR1171 Optické diaľkomery]() High speed sensors also for outdoor applications

High speed sensors also for outdoor applications - optoNCDT ILR2250

![optoNCDT ILR2250 Optické diaľkomery]() High-performance laser distance sensors

High-performance laser distance sensors - optoNCDT ILR3800

![optoNCDT ILR3800 Optické diaľkomery]() High-performance laser distance sensor for industrial applications

High-performance laser distance sensor for industrial applications - optoNCDT ILR104x

![optoNCDT ILR104x Optické diaľkomery]() Compact and reliable laser distance sensor

Compact and reliable laser distance sensor

- optoNCDT ILR1030/1031

- Lineárne induktívne snímače (LVDT)

- induSENSOR DTD gauge

![induSENSOR DTD gauge Lineárne induktívne snímače (LVDT)]() Push-button with compact cable controller

Push-button with compact cable controller - induSENSOR DTA dotyk

![induSENSOR DTA dotyk Lineárne induktívne snímače (LVDT)]() LVDT gauges

LVDT gauges - induSENSOR DTA

![induSENSOR DTA Lineárne induktívne snímače (LVDT)]() LVDT displacement sensors

LVDT displacement sensors - induSENSOR LDR

![induSENSOR LDR Lineárne induktívne snímače (LVDT)]() Linear displacement sensors

Linear displacement sensors - Snímač pro kontrolu upínací polohy

![Snímač pro kontrolu upínací polohy Lineárne induktívne snímače (LVDT)]() Sensors for monitoring the clamping position

Sensors for monitoring the clamping position - Kontrolér MSC7x0x

![Kontrolér MSC7x0x Lineárne induktívne snímače (LVDT)]()

- induSENSOR EDS

![induSENSOR EDS Lineárne induktívne snímače (LVDT)]() Long-stroke sensors with integrated electronics

Long-stroke sensors with integrated electronics - Specifické snímače zákazníků

![Specifické snímače zákazníků Lineárne induktívne snímače (LVDT)]()

- induSENSOR DTD gauge

- Magneto-indukční snímače

- mainSENSOR MDS-35/-45

![mainSENSOR MDS-35/-45 Magneto-indukční snímače]() Robust sensors with M12, M18 and M30 design

Robust sensors with M12, M18 and M30 design - mainSENSOR MDS-40-MK

![mainSENSOR MDS-40-MK Magneto-indukční snímače]() Sensors for series applications

Sensors for series applications - mainSENSOR MDS-40-LP

![mainSENSOR MDS-40-LP Magneto-indukční snímače]() Sensors with circuit-board design

Sensors with circuit-board design - Specifické snímače

![Specifické snímače Magneto-indukční snímače]()

- mainSENSOR MDS-35/-45

- Lankové snímače

- Lankové snímače pro integraci a OEM

![Lankové snímače pro integraci a OEM Lankové snímače]() Miniature sensors with plastic housing

Miniature sensors with plastic housing - Průmyslové lankové snímače

![Průmyslové lankové snímače Lankové snímače]() Robust sensors with aluminum housing

Robust sensors with aluminum housing - Lankové snímače pro rychlá měření

![Lankové snímače pro rychlá měření Lankové snímače]() For high wire accelerations

For high wire accelerations - Mechanika

![Mechanika Lankové snímače]() Draw-wire mechanisms for encoder mounting

Draw-wire mechanisms for encoder mounting

- Lankové snímače pro integraci a OEM

- Káblový navijak pre žeriavy

- Snímače vzdialenosti s vírivým prúdom

- Priemyselné senzory

- 2D / 3D měření

- 2D / 3D měření

- Optické mikrometre

- optoCONTROL 1200

![optoCONTROL 1200 Optické mikrometre]() Compact high-speed micrometer

Compact high-speed micrometer - optoCONTROL 2520

![optoCONTROL 2520 Optické mikrometre]() Compact laser micrometer (class 1M)

Compact laser micrometer (class 1M) - optoCONTROL 2700

![optoCONTROL 2700 Optické mikrometre]() High-performance micrometer for the highest demands

High-performance micrometer for the highest demands

- optoCONTROL 1200

- Laserové skenery profilu

- Konfigurátor

- scanCONTROL 25x0

![scanCONTROL 25x0 Laserové skenery profilu]() Laser scanner for series applications

Laser scanner for series applications - scanCONTROL 29x0

![scanCONTROL 29x0 Laserové skenery profilu]() Compact laser scanners with high precision

Compact laser scanners with high precision - scanCONTROL 30x2

![scanCONTROL 30x2 Laserové skenery profilu]() Powerful 2D/3D laser scanners

Powerful 2D/3D laser scanners - scanCONTROL 30x0

![scanCONTROL 30x0 Laserové skenery profilu]() High-performance laser scanners

High-performance laser scanners - Software

- Příslušenství

- Aplikace

- Inšpekčné systémy

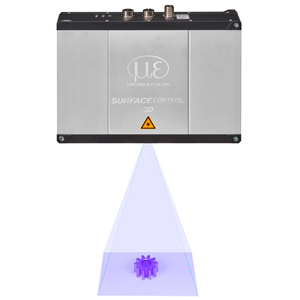

- Sensor systems for precise 3D and thickness measurement

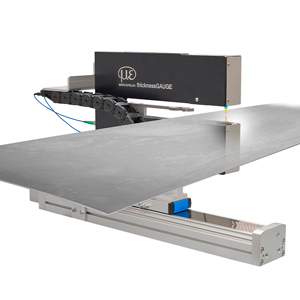

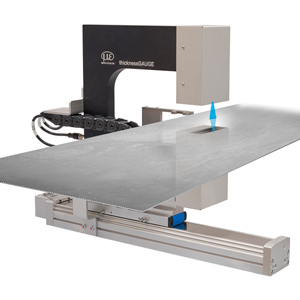

- thicknessGAUGE 3D

![thicknessGAUGE 3D Sensor systems for precise 3D and thickness measurement]() Inline thickness and profile measurements

Inline thickness and profile measurements - thicknessGAUGE C.LL

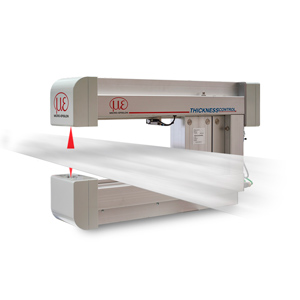

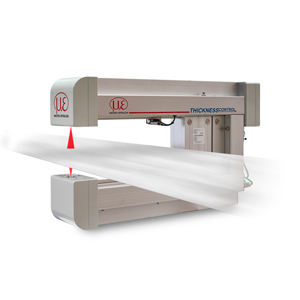

![thicknessGAUGE C.LL Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (laser sensors)

Inline thickness measurement (laser sensors) - thicknessGAUGE C.C

![thicknessGAUGE C.C Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (confocal)

Inline thickness measurement (confocal) - thicknessGAUGE C.LP

![thicknessGAUGE C.LP Sensor systems for precise 3D and thickness measurement]() Inline-Dickenmessung (Laser-Profilsensoren)

Inline-Dickenmessung (Laser-Profilsensoren) - thicknessGAUGE O.EC

![thicknessGAUGE O.EC Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (eddy current/capacitive)

Inline thickness measurement (eddy current/capacitive)

- thicknessGAUGE 3D

- Measuring and inspection systems for metals

- Measuring and inspection systems for the automotive industry

- Measuring systems for the battery production

- Inspection and production systems for the tire industry

- Měřicí a inspekční systémy pro plasty

- Sensor systems for precise 3D and thickness measurement

- Aplikace

- Průmysl

- Výroba aditiv

- Letectví

- Automatizace

- Automobilový průmysl

- Battery production

- Structural monitoring & Building material production

- Výroba elektroniky

- Energetická technologie

- Sklo

- Polovodiče

- Plasty

- Kontrola barev

- Strojírenství

- Lékařská technologie

- Metrologie a zkušební technologie

- Kovovýroba

- Mobilní zařízení

- Optické systémy

- Tracks & Rail traffic

- Typické příklady použití

- Průmysl

- Kontakty