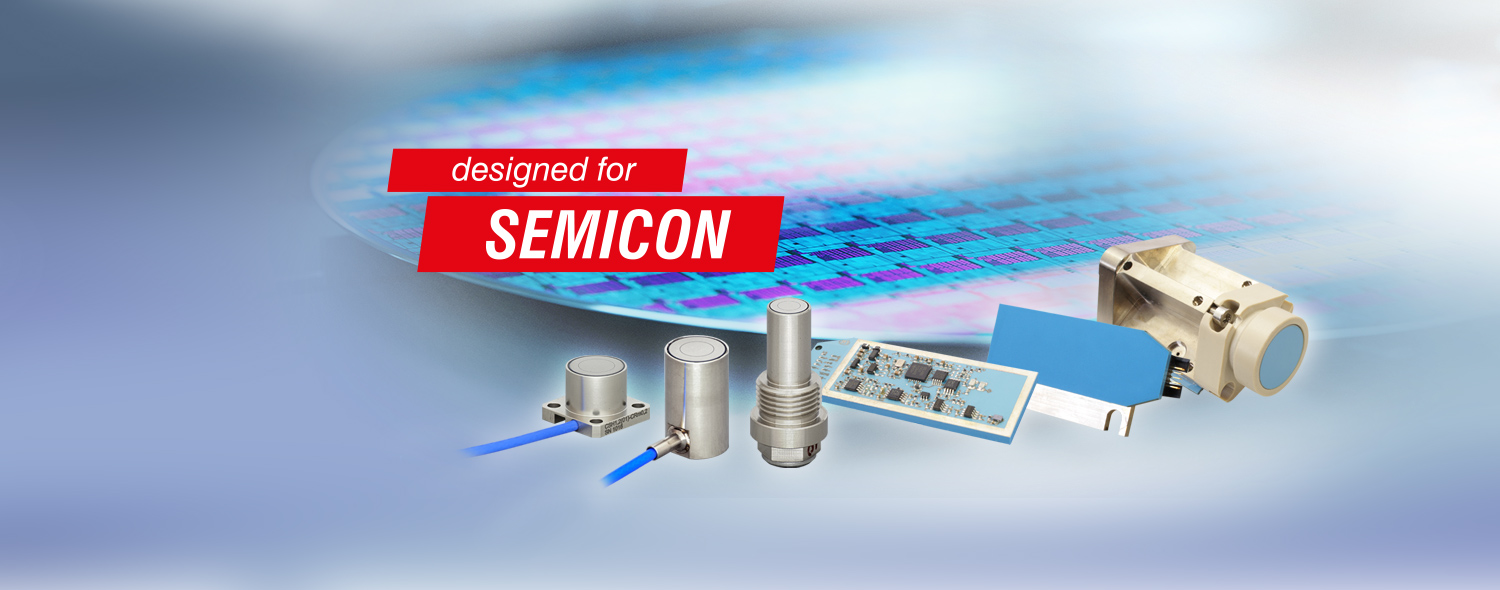

Vysoce přesné snímače vzdálenosti pro sériové aplikace OEM v polovodičovém inženýrství

Senzorová technologie společnosti Micro-Epsilon se již mnoho let úspěšně používá v polovodičovém průmyslu a nabízí správné řešení pro jakýkoli měřicí úkol: Nabízíme ultra přesné senzory pro komplexní frontend procesy, backend aplikace a automatizaci manipulace s wafery. Naše senzorová řešení vynikají vysokou přesností, spolehlivostí a dlouhodobou stabilitou – i za náročných procesních podmínek v různých výrobních prostředích.

Proč Micro-Epsilon?

- Více přesnosti v řádech pikometrů - Vyrobeno v Německu

- Poradenství, vývoj a výroba z jediného zdroje

- Společně s našimi zákazníky: kvalita a řešení problémů v sériích a OEM

- Hluboké technologické a aplikační znalosti v oblasti výroby polovodičů

- Moderní výrobní metody pro vysoce přesné snímače posunutí a senzorové systémy

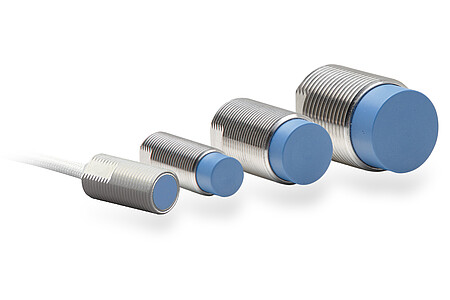

Optimalizované senzory pro aplikace v sériové výrobě OEM

Pro sériové aplikace upravujeme naše senzory podle vašich specifikací, např. změny kabelu, materiálu a konstrukce senzoru i kontroléru. Kromě toho se používají také materiály senzorů specifické pro danou aplikaci.

Typické specifikace senzorů pro sériové aplikace:

- Vhodné pro vakuové prostředí: materiály s nízkým odplyňováním a výrobní technologie splňující požadavky UHV

- Speciální spojovací technologie

- Označování a balení v souladu s normami polovodičového průmyslu

- Optimalizace výkonu pro výjimečnou přesnost měření

- Maximální odolnost proti elektromagnetickým polím

- Vysoké standardy zajištění kvality ve všech fázích procesu

Připraveni na polovodiče – optimalizované výrobní metody

Všechny senzory a systémy procházejí komplexními výrobními a testovacími postupy. To se týká mimo jiné výběru a umístění elektroniky, mechanického výrobního postupu a speciální procesní technologie.

Vysoce specializované výrobní metody

- Laserová technologie USP

- Vysokoteplotní vakuové pájení

- Mechanická přesná výroba

- Zahořovací testy

- Plně automatizované linky pro zalévání

- Pasivace a povrchová úprava komponentů

- Specializované čisticí procesy

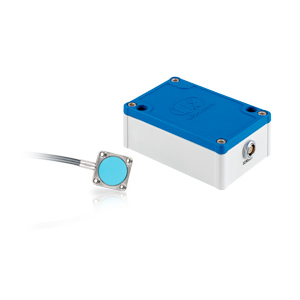

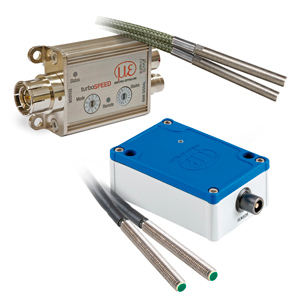

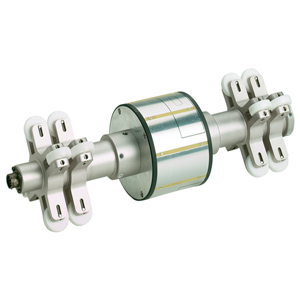

Technologie vestavěných cívek

Pro zvláště náročné projekty OEM doporučujeme použít technologii vestavěných cívek nebo technologii vestavěných kondenzátorů (ECT). Díky miniaturizované konstrukci senzoru z anorganického materiálu je možné dosáhnout téměř všech stupňů volnosti vnějšího tvaru. Díky keramickému substrátu jsou senzory mechanicky odolné a extrémně stabilní. V případě potřeby lze do senzoru integrovat celou vyhodnocovací elektroniku. To umožňuje přizpůsobit senzory ECT speciálním instalačním podmínkám. Senzory ECT jsou vhodné pro nejnáročnější podmínky použití a osvědčily se v mnoha aplikacích.

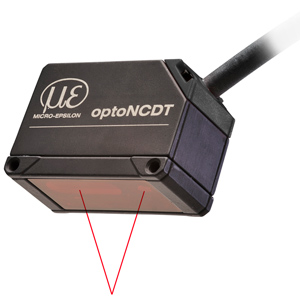

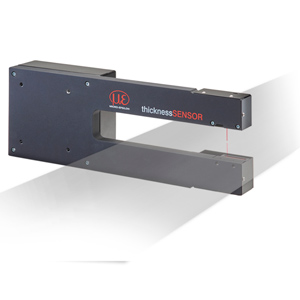

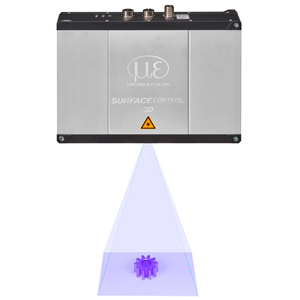

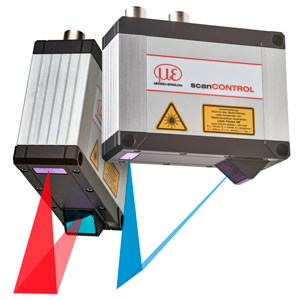

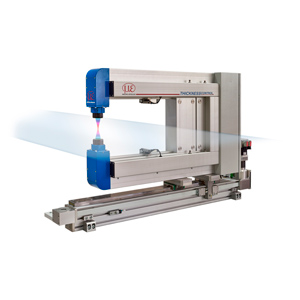

Větší přesnost pro polovodičový průmysl

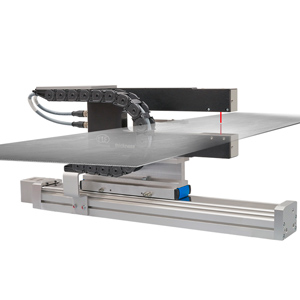

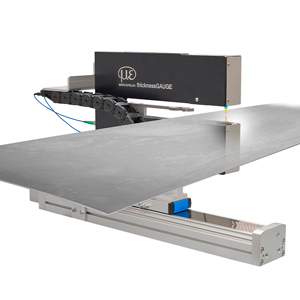

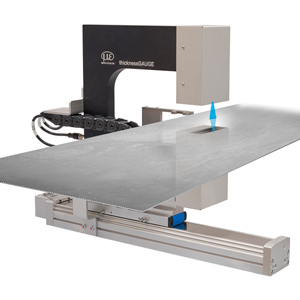

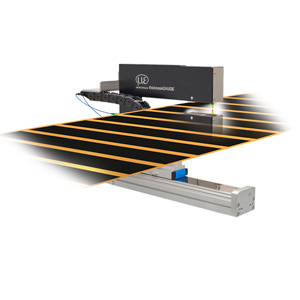

Společnost Micro-Epsilon nabízí správné řešení pro nejrůznější aplikace v polovodičovém průmyslu – od vysoce přesného optického polohování a vyrovnávání traversních systémů až po hybridní spojování silikonových plátů. Senzory se používají jak ve frontend, tak v backend procesech a vynikají nejvyšší přesností a spolehlivostí.